Maximizing Fleet Performance with Equipment Tracking Technology

In the high-pressure industries construction, logistics, or transportation efficiently managing a fleet can make or break your operations. Fleet managers balance the demands of keeping assets in the right place at the right time, ensuring minimal downtime, and controlling escalating operational costs. However, with larger fleets and more complex projects, traditional management approaches are falling short.

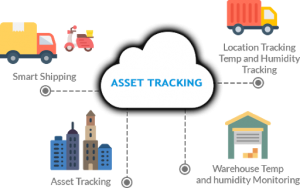

Equipment tracking technology. This game-changing solution offers unprecedented insight into every piece of equipment's location, performance, and health. Gone are the days of manual oversight, guesswork, or inefficiency. With equipment tracking technology, businesses can harness real-time data to streamline fleet management, optimize resource allocation, and maximize fleet performance.

This blog will explore how construction equipment tracking software and other equipment tracking solutions can reduce costs, boost operational efficiency, and help businesses maintain a competitive edge.

The Need for Efficient Fleet Management

Managing a fleet is no small task. It's a juggling act involving maintenance schedules, fuel consumption, and asset allocation while trying to prevent theft and equipment misuse. Without proper oversight, it's easy for these areas to spiral out of control.

Operational Challenges

- Maintenance Issues: Maintaining maintenance schedules for multiple vehicles and equipment is a constant challenge. Missed or delayed servicing can result in unexpected breakdowns and costly repairs.

- Fuel Inefficiency: Fuel is one of the largest operational costs in fleet management. Without proper tracking, fuel inefficiency caused by poor driving habits, idling, or inefficient routes can quickly eat into profit margins.

- Asset Mismanagement: Ensuring that equipment is where it needs to be when it needs to be is critical to keeping projects on schedule. Misplaced or underutilized assets lead to delays, lost revenue, and project inefficiencies.

The Consequences of Poor Oversight

When fleet management is handled manually, errors are inevitable, and those errors can be costly. Downtime increases as equipment sits idle, project delays pile up, and operational costs skyrocket. Without the proper tools to monitor and manage your fleet, you could face frequent breakdowns, higher fuel expenses, and even potential security breaches.

A lack of real-time visibility into your fleet's performance means inefficiencies will go unchecked, impacting your bottom line. In competitive industries like construction and logistics, companies that fail to optimize their fleet operations often lose ground to competitors who do.

Why Fleet Performance Matters

Maximizing fleet performance is no longer a luxury it's necessary to stay competitive. Optimizing fleet performance can mean the difference between success and failure in industries with tight profit margins. Improved fleet performance leads to the following:

- Reduced Operational Costs: Through better fuel efficiency and lower maintenance expenses.

- Increased Productivity: By ensuring equipment is available and operational when needed.

- Improved Resource Allocation: Tracking where and how equipment is being used better.

Now that we've established the importance of efficient fleet management let's explore equipment tracking technology's role in maximizing fleet performance.

What is Equipment Tracking Technology

Equipment tracking technology encompasses a variety of systems GPS, RFID, and telematics designed to monitor and report the real-time status of your assets. Whether it's a truck, excavator, or even a small generator, equipment tracking gives fleet managers the power to oversee operations from a central platform.

- GPS Tracking: Global Positioning System (GPS) trackers provide real-time updates on the location of vehicles and equipment, allowing fleet managers to monitor usage and movements.

- RFID Tracking: Radio-frequency identification (RFID) technology is often used for smaller equipment. It tracks assets within a specific range and helps manage inventory.

- Telematics refers to the integrated use of telecommunications and information processing to send, receive, and store real-time data from fleet vehicles and equipment.

Key Benefits of Equipment Tracking for Fleet Performance

Real-Time Location Tracking

With real-time location tracking, fleet managers know exactly where every piece of equipment is. Whether on-site, en route, or at a storage facility, the visibility allows for efficient dispatching and ensures that assets are where they are supposed to be.

- Example: Companies using real-time location tracking can reduce idle time by up to 25%, leading to better resource allocation and quicker project completion.

- Preventive Maintenance

Imagine always taking advantage of another maintenance check. With equipment tracking technology, automated maintenance alerts ensure that servicing schedules are followed diligently. This prevents expensive breakdowns, extends the lifespan of equipment, and avoids costly project delays.

- Statistic: Companies implementing preventive maintenance through tracking systems see a 20-30% reduction in unplanned downtime.

Fuel Efficiency & Cost Control

Monitoring driver behavior and equipment usage can significantly impact fuel consumption. Using construction equipment tracking software, managers can detect idling vehicles, inefficient routes, and other factors contributing to excessive fuel usage. As a result, they can adjust routes, train drivers, and save thousands in fuel costs.

- Fact: Fleet managers can cut fuel expenses by as much as 15% by optimizing driver behavior and route planning.

Improved Security

Equipment theft and unauthorized usage are pressing concerns in industries like construction, where assets are expensive and often left unattended. With geofencing features—creating virtual boundaries around job sites—fleet managers are immediately alerted when equipment moves outside the designated area.

- Fact: Adopting equipment tracking technology has led to a 50% reduction in theft incidents in some industries.

Enhanced Reporting & Analytics

Data is one of the most valuable assets a fleet manager can have. Equipment tracking systems provide detailed reports that help track key performance indicators (KPIs), such as fuel consumption, maintenance schedules, and asset utilization. This information allows managers to make informed decisions to improve operational efficiency, reduce costs, and maximize fleet performance.

- Example: Analyzing fleet data can help identify underutilized assets, leading to savings by avoiding unnecessary purchases.

Conclusion

Maximizing fleet performance is essential to operational success in the competitive landscape. Equipment tracking technology has revolutionized the way businesses monitor and manage their fleets. The benefits are undeniable, from improving fuel efficiency to ensuring preventive maintenance and boosting asset security. Companies that leverage construction equipment tracking software are reaping the rewards of reduced costs, enhanced productivity, and streamlined operations.

- Questions and Answers

- Opinion

- Story/Motivational/Inspiring

- Technology

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News

- Culture

- War machines and policy