Polycarbonate sheets have revolutionized the construction and architectural industries by providing materials that offer durability, light transmission, and flexibility. Among the different types of polycarbonate sheets, the PC hollow sheet stands out as an exceptional choice for various applications. It combines strength, lightness, and transparency, making it a popular choice in roofing, glazing, greenhouses, and interior design. This article will explore the benefits, uses, and features of hollow polycarbonate sheets and why they are becoming increasingly favored in construction projects worldwide.

What is a Hollow Polycarbonate Sheet?

A hollow polycarbonate sheet is a lightweight plastic sheet with a hollow structure, providing excellent insulation, strength, and flexibility. The sheet consists of two or more layers of polycarbonate material separated by vertical ribs, forming hollow chambers between the layers. This unique structure allows for high impact resistance while maintaining a low weight, which makes it ideal for projects where both durability and ease of installation are crucial.

The hollow structure of the sheet provides excellent thermal insulation, making it energy-efficient for buildings and greenhouses. Moreover, it offers high optical clarity, allowing natural light to pass through, which makes it suitable for applications such as skylights, canopies, and partitions.

Why Choose Hollow Polycarbonate Sheets for Construction?

One of the key reasons why Hollow polycarbonate sheet are preferred in construction is their superior durability combined with their lightweight properties. Unlike glass or solid plastic sheets, hollow polycarbonate sheets offer better impact resistance while being easier to handle and install. This makes them especially useful for large-scale projects, where the material needs to be moved or installed at height.

Another significant advantage is the sheet’s weather-resistant nature. Polycarbonate is naturally UV-resistant, which means the hollow polycarbonate sheet won’t yellow, crack, or degrade when exposed to sunlight over time. This property makes it an excellent choice for outdoor applications like greenhouses, awnings, and carports, where constant exposure to the elements is inevitable.

The insulation properties of hollow sheets make them suitable for energy-efficient construction, helping to reduce heating and cooling costs in buildings. Additionally, they are versatile enough to be used in creative interior designs, such as partitions, which require translucency but also strength.

Advantages of PC Hollow Sheets in Architectural Applications

-

Lightweight and Durable: PC hollow sheets weigh significantly less than solid sheets or glass, making them easier to transport and install without compromising on durability. Their high impact resistance ensures they are tough enough to withstand harsh weather conditions and mechanical stress.

-

Thermal Insulation: The hollow structure of the sheet creates insulating air spaces between layers, reducing heat transfer. This feature is particularly useful in greenhouses, conservatories, or any application where energy efficiency is a priority.

-

Transparency and Light Diffusion: The excellent light diffusion properties of hollow polycarbonate sheets make them ideal for roofing and glazing applications. They allow natural light to pass through while reducing glare, creating a pleasant and energy-efficient environment inside.

-

UV Protection: Hollow polycarbonate sheets come with a UV-protective layer, which prevents harmful ultraviolet rays from passing through while also protecting the sheet itself from sun damage.

-

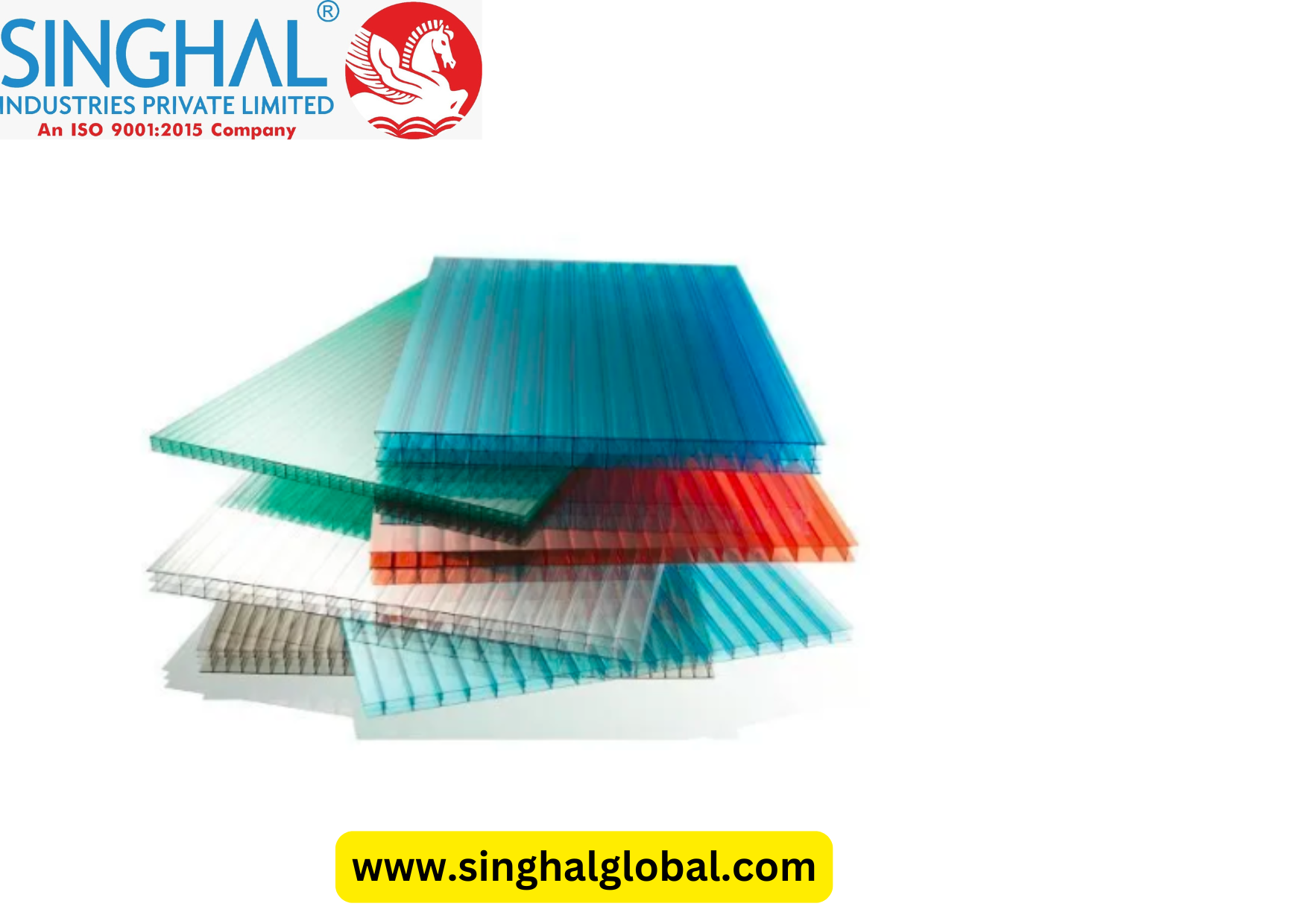

Versatility in Design: These sheets are available in a variety of colors, sizes, and thicknesses, making them suitable for a wide range of design possibilities. They can be bent, shaped, or cut to fit specific architectural needs without losing their structural integrity.

Applications of Hollow Sheet Polycarbonate in Construction

The uses of Hollow sheet polycarbonate are vast and varied, making them a favorite among architects and builders. Here are some of the most common applications:

-

Greenhouses: Thanks to their high light transmission and thermal insulation properties, hollow polycarbonate sheets are widely used in greenhouses. They provide the perfect balance between light penetration and temperature control, creating an ideal environment for plant growth.

-

Skylights and Roof Glazing: The lightweight nature of PC hollow sheets makes them ideal for skylights and roof glazing. They allow ample natural light into the building while offering protection against the elements. Their UV-resistant properties ensure they remain clear and functional for years.

-

Partitions and Wall Panels: Hollow polycarbonate sheets are often used in interior spaces as partitions or wall panels. Their translucent nature provides privacy without blocking out light, making them perfect for offices, meeting rooms, and modern homes.

-

Carports and Pergolas: For outdoor structures like carports and pergolas, hollow polycarbonate sheets offer a durable and aesthetically pleasing roofing solution. They protect against rain and UV rays while letting in filtered light.

-

Signage and Advertising: Their ability to withstand harsh environmental conditions makes hollow polycarbonate sheets suitable for outdoor signage and advertising displays. Their lightweight nature also makes them easy to install in large sizes.

Key Benefits of Hollow Polycarbonate Sheets in Greenhouses

One of the primary applications for hollow polycarbonate sheets is in the construction of greenhouses. The material’s superior insulation properties help maintain a consistent internal temperature, which is crucial for the growth and health of plants. Additionally, the sheets’ ability to diffuse light ensures that sunlight is spread evenly across the interior, preventing any hot spots or uneven growth patterns.

The durability of hollow sheet polycarbonate ensures that greenhouses can withstand harsh weather conditions such as hail, wind, and heavy rain without sustaining damage. Unlike glass, polycarbonate won’t shatter or crack under stress, making it a much safer option for greenhouses located in areas prone to severe weather.

Environmental Benefits and Sustainability

Polycarbonate sheets, including PC hollow sheet, are recyclable, adding an eco-friendly dimension to their use. Many manufacturers are now producing polycarbonate sheets that are made from recycled materials, which further reduces their environmental impact. For construction companies and architects looking to implement sustainable building practices, using hollow polycarbonate sheets can contribute to greener construction and energy efficiency.

Moreover, the long lifespan of hollow polycarbonate sheets means that they require less frequent replacement, reducing the need for new materials and minimizing waste over time.

Conclusion

In the world of modern construction, PC hollow sheets have proven themselves to be an invaluable material. Their combination of lightweight structure, high impact resistance, thermal insulation, and transparency makes them ideal for a wide range of applications, from greenhouses to architectural glazing. As the demand for energy-efficient and durable materials grows, hollow polycarbonate sheets will continue to play a significant role in shaping the future of construction.

Here are Related For Hollow sheet polycarbonate

Q1: How do hollow polycarbonate sheets compare to solid polycarbonate sheets?

Ans: Hollow polycarbonate sheets are lighter and provide better thermal insulation than solid sheets, making them ideal for applications where weight and energy efficiency are important.

Q2: Can PC hollow sheets be used for outdoor structures?

Ans: Yes, PC hollow sheets are UV-resistant and weatherproof, making them perfect for outdoor applications such as carports, pergolas, and skylights.

Q3: What are the key advantages of using hollow polycarbonate sheets in greenhouses?

Ans: Hollow polycarbonate sheets provide excellent thermal insulation, high light transmission, and durability, creating the ideal environment for plant growth in greenhouses.