In today's competitive market, businesses are constantly seeking ways to enhance product quality while keeping costs manageable. One material that has gained significant attention for its cost-effectiveness and durability is polypropylene (PP) fibrillated yarn. This innovative PP Fibrillated Yarn Price a range of benefits that make it an attractive option for various applications, from packaging to industrial textiles. In this blog, we will explore how PP fibrillated yarn contributes to cost-effective and durable products and why it is becoming a preferred choice for many industries.

What is PP Fibrillated Yarn?

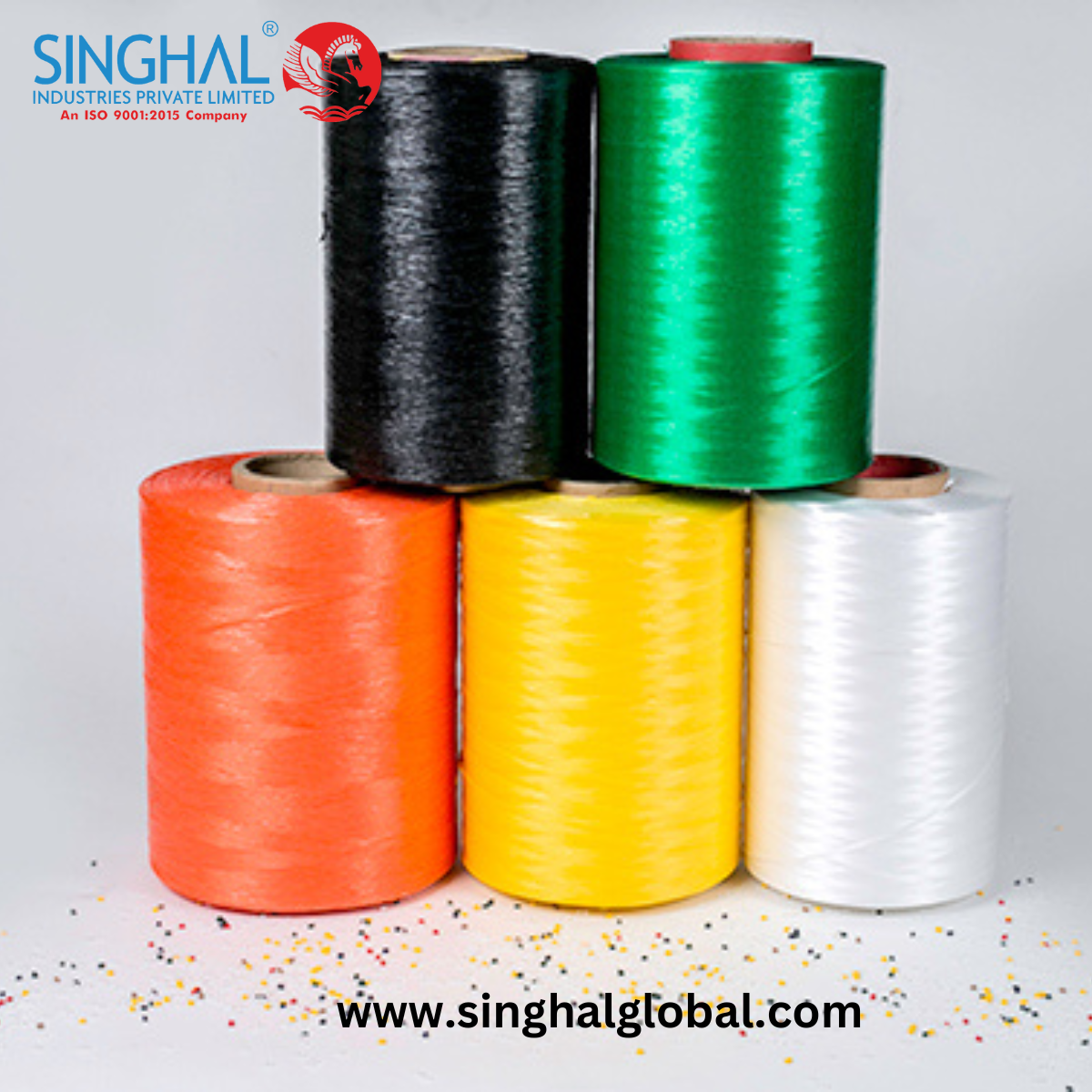

PP fibrillated yarn is made from polypropylene, a versatile thermoplastic polymer. The term "fibrillated" refers to the process of splitting the yarn into fine, filament-like strands that create a mesh-like PP Fibrillated Yarn Suppliers. This fibrillation process enhances the yarn's properties, making it suitable for a wide range of applications. The result is a strong, flexible yarn with excellent resistance to abrasion, chemicals, and environmental factors.

Cost-Effectiveness of PP Fibrillated Yarn

1. Lower Raw Material Costs

One of the primary reasons PP fibrillated yarn is cost-effective is the relatively low cost of polypropylene as a raw material. Polypropylene is an abundant and inexpensive polymer compared to other materials like nylon or polyester. This inherent cost advantage translates into lower production costs for products made with PP fibrillated yarn, making it an economically viable option for manufacturers.

2. Reduced Production Costs

The production process for PP fibrillated yarn is efficient and straightforward. The yarn is created by extruding polypropylene and then subjecting it to a fibrillation process that splits the yarn into fine filaments. This method is less complex and energy-intensive compared to the production of other types of yarn, resulting in reduced manufacturing costs. Additionally, PP fibrillated yarn's durability and resistance to wear mean that products made from it require less frequent replacement, further driving down long-term costs.

3. Minimal Maintenance Requirements

Products made from PP fibrillated yarn are known for their low maintenance needs. The yarn's resistance to moisture, chemicals, and UV radiation ensures that it retains its strength and appearance over time. This durability reduces the need for frequent cleaning or repairs, contributing to lower maintenance costs for end users. For businesses, this translates into savings on maintenance and replacement expenses.

Durability of PP Fibrillated Yarn

1. Superior Strength and Resilience

PP fibrillated yarn is renowned for its exceptional strength and resilience. The fibrillation process creates a mesh-like structure that enhances the yarn's ability to withstand heavy loads and resist abrasion. This makes PP fibrillated yarn ideal for applications where durability is crucial, such as in industrial textiles, geotextiles, and packaging materials. The yarn's strength ensures that products made from it can endure harsh conditions and prolonged use without significant wear or damage.

2. Resistance to Environmental Factors

One of the standout features of PP fibrillated yarn is its resistance to various environmental factors. Unlike natural fibers, polypropylene is not prone to degradation from moisture, mold, or UV radiation. This makes PP fibrillated yarn particularly suitable for outdoor applications and environments with high humidity or exposure to sunlight. For example, PP fibrillated yarn is commonly used in agricultural applications, where it can withstand exposure to soil, water, and sunlight without deteriorating.

3. Chemical Resistance

PP fibrillated yarn exhibits excellent resistance to a wide range of chemicals, including acids, bases, and solvents. This property makes it an ideal choice for applications where exposure to harsh chemicals is a concern. For instance, in the industrial sector, PP fibrillated yarn is used in chemical-resistant fabrics and filtration materials. Its chemical resistance ensures that products maintain their integrity and performance even when exposed to aggressive substances.

Applications of PP Fibrillated Yarn

1. Packaging Materials

In the packaging industry, PP fibrillated yarn is used to manufacture strong and durable packaging materials such as woven sacks and bags. The yarn's strength and resistance to abrasion make it suitable for heavy-duty packaging applications, including the transport of agricultural products, construction materials, and industrial goods. The cost-effectiveness of PP fibrillated yarn also helps keep packaging costs competitive.

2. Geotextiles and Construction

PP fibrillated yarn is widely used in geotextiles for civil engineering and construction projects. The yarn's durability and resistance to environmental factors make it an excellent choice for applications such as soil stabilization, erosion control, and drainage systems. Geotextiles made from PP fibrillated yarn provide long-lasting performance and contribute to the stability and longevity of construction projects.

3. Industrial Textiles

In the industrial sector, PP fibrillated yarn is employed in various textile products, including conveyor belts, protective clothing, and filtration materials. The yarn's strength and chemical resistance ensure that these products can withstand the demands of industrial environments. Additionally, the low production and maintenance costs of PP fibrillated yarn contribute to cost-effective solutions for industrial applications.

4. Agriculture

In agriculture, PP fibrillated yarn is used in applications such as netting, mulch mats, and erosion control fabrics. The yarn's resistance to moisture, UV radiation, and chemicals makes it suitable for outdoor agricultural environments. It provides protection to crops and soil, reduces erosion, and supports sustainable farming practices.

Future Trends and Innovations

The use of PP fibrillated yarn continues to evolve as industries seek more sustainable and efficient materials. Innovations in yarn production and applications are expected to further enhance the benefits of PP fibrillated yarn. Advances in recycling technologies may enable more sustainable use of polypropylene, and ongoing research may lead to improved properties and applications of fibrillated yarn.

Conclusion

PP fibrillated yarn is a versatile and cost-effective material that offers exceptional durability and performance across various applications. Its advantages, including lower raw material and production costs, minimal maintenance requirements, and resistance to environmental factors, make it an attractive choice for businesses looking to enhance product quality while managing costs. From packaging and industrial textiles to geotextiles and agricultural applications, PP fibrillated yarn provides a robust solution that Fibrillated Polypropylene Yarn the demands of modern industries. As sustainability and efficiency become increasingly important, PP fibrillated yarn stands out as a valuable asset in creating cost-effective and durable products.

Frequently Asked Questions (FAQs):

1. How does Singhal Industries’ PP fibrillated yarn contribute to cost-effective manufacturing?

Singhal Industries’ PP fibrillated yarn is designed to be a cost-effective solution for manufacturing due to its affordable raw material costs and efficient production process. Polypropylene, the base material, is relatively inexpensive, which helps lower overall production expenses. The straightforward production method of fibrillating the yarn reduces energy consumption and manufacturing complexity. Additionally, the durability and resistance of Singhal Industries’ PP fibrillated yarn mean that products require less frequent replacement and maintenance, further contributing to long-term cost savings.

2. What are the durability advantages of using PP fibrillated yarn from Singhal Industries?

PP fibrillated yarn from Singhal Industries offers significant durability advantages due to its robust structure and resistance to environmental factors. The fibrillation process creates a mesh-like pattern that enhances the yarn’s strength and abrasion resistance, making it suitable for demanding applications. Singhal Industries’ yarn is resistant to moisture, UV radiation, and a wide range of chemicals, which ensures that it performs well in various conditions and maintains its integrity over time. This durability is ideal for applications such as industrial textiles, packaging, and geotextiles, where long-lasting performance is crucial.

3. In what applications is Singhal Industries’ PP fibrillated yarn most commonly used?

Singhal Industries’ PP fibrillated yarn is widely utilized in several key applications due to its strength and versatility. In the packaging industry, it is used to produce durable woven sacks and bags that handle heavy loads. For construction and geotechnical projects, Singhal Industries’ yarn is employed in geotextiles to provide soil stabilization and erosion control. In industrial settings, the yarn is used in products like conveyor belts and filtration materials. Additionally, in agriculture, it is used for netting and erosion control fabrics. The broad applicability of Singhal Industries’ PP fibrillated yarn demonstrates its effectiveness across diverse industries.