Troubleshooting Common Issues with PP Fibrillated Yarn

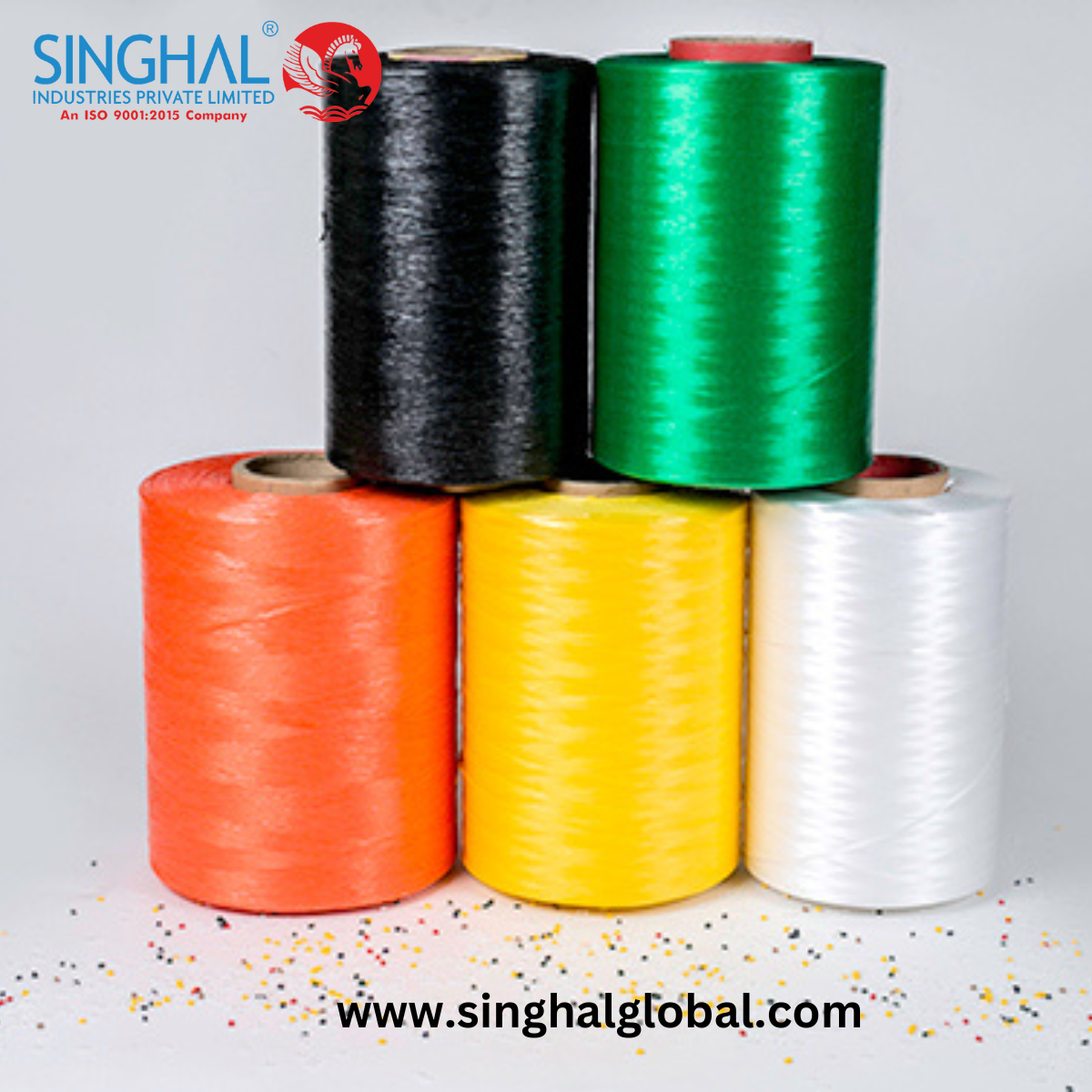

Polypropylene (PP) fibrillated yarn is a versatile material widely used in various industries due to its strength, durability, and cost-effectiveness. Commonly found in applications ranging from geotextiles and industrial fabrics to packaging and reinforcement materials, PP Fibrillated Yarn Price plays a crucial role in many manufacturing processes. However, like any material, it can present challenges during production. This blog will explore common issues faced in the manufacturing of PP fibrillated yarn and provide practical solutions to troubleshoot these problems.

Understanding PP Fibrillated Yarn

PP fibrillated yarn is created by splitting or fibrillating polypropylene fibers into numerous fine filaments. This process enhances the yarn's texture and increases its surface area, making it ideal for PP Fibrillated Yarn Suppliers requiring high strength and durability. The yarn is commonly used in woven fabrics, where its fibrillated nature improves adhesion and reinforcement.

Common Issues and Their Solutions

1. Inconsistent Yarn Thickness

Problem: One of the most common issues in manufacturing PP fibrillated yarn is inconsistent yarn thickness. This can lead to uneven fabric strength and appearance, impacting the quality of the final product.

Solution: To address this issue, ensure that the extrusion process is carefully monitored. Variations in temperature, pressure, or extrusion speed can affect yarn thickness. Regularly calibrate and maintain extrusion equipment to ensure consistent performance. Additionally, using high-quality polypropylene resin and controlling the fibrillation process accurately can help achieve uniform yarn thickness.

2. Poor Fibrillation Quality

Problem: The fibrillation process can sometimes result in poor quality, where the fibers do not separate properly, leading to weak and ineffective yarn.

Solution: Ensure that the fibrillation equipment is correctly set up and maintained. The process should be optimized for the specific type of polypropylene used. Adjust the fibrillation parameters, such as pressure and temperature, to achieve the desired level of fibrillation. Regular inspection of the equipment and the yarn produced can help identify and rectify issues promptly.

3. Yarn Fraying and Breakage

Problem: Yarn fraying or breakage during production can result in defective products and reduced efficiency in the manufacturing process.

Solution: Yarn fraying often occurs due to improper handling or tension settings. Ensure that the yarn is handled carefully during production and that machinery is correctly adjusted to manage tension. Regularly check for sharp edges or obstructions in the machinery that might cause damage to the yarn. Additionally, incorporating quality control measures, such as inspecting the yarn for strength and consistency, can help mitigate this issue.

4. Color Variations

Problem: Color variations in PP fibrillated yarn can be problematic, especially when producing products with specific color requirements.

Solution: Color variations can result from inconsistent dyeing processes or variations in the polypropylene resin. To address this, ensure that the dyeing process is well-controlled and that dye batches are consistent. Use high-quality dyes and maintain precise dyeing conditions. Additionally, ensure that the polypropylene resin used is of consistent quality and color.

5. Uneven Fibrillation Distribution

Problem: Uneven distribution of fibrillated fibers can affect the overall performance of the yarn, leading to weak spots and inconsistent fabric quality.

Solution: Optimize the fibrillation process to ensure even distribution of fibers. Regularly calibrate the fibrillation equipment and check for any wear or damage that could affect the distribution. Implement quality control checks during production to identify and address any inconsistencies early.

6. Clogging and Blockages

Problem: Clogging and blockages in the extrusion or fibrillation equipment can disrupt production and affect yarn quality.

Solution: Regularly clean and maintain all equipment to prevent clogs and blockages. Implement a routine maintenance schedule that includes checking for debris or buildup in the equipment. Use filters and screens where necessary to keep the equipment clean and functioning properly.

7. Inadequate Adhesion in Woven Fabrics

Problem: PP fibrillated yarn is often used in woven fabrics, where adhesion between fibers is crucial. Inadequate adhesion can result in weak fabrics and reduced performance.

Solution: Ensure that the fibrillation process creates a sufficient surface area for adhesion. Properly control the fibrillation parameters to enhance the yarn’s texture and bonding capabilities. Additionally, consider applying surface treatments or coatings to improve adhesion in specific applications.

8. Variability in Yarn Strength

Problem: Variability in yarn strength can lead to inconsistencies in the final product, affecting its durability and performance.

Solution: To ensure consistent yarn strength, closely monitor and control the extrusion and fibrillation processes. Regularly test the yarn for strength and adjust the manufacturing parameters as needed. Implementing a robust quality control system can help identify and address any strength variability early in the production process.

9. Machine Wear and Tear

Problem: Over time, machinery used in the production of PP fibrillated yarn can experience wear and tear, leading to production issues.

Solution: Implement a regular maintenance schedule for all machinery to address wear and tear. Replace worn-out parts promptly and perform routine checks to ensure that equipment is functioning correctly. Investing in high-quality, durable machinery can also help reduce the frequency of maintenance and repair.

10. Temperature Fluctuations

Problem: Fluctuations in temperature during the extrusion or fibrillation processes can affect yarn quality and consistency.

Solution: Maintain a stable temperature environment throughout the production process. Use temperature control systems to monitor and regulate the temperature of the equipment. Regularly calibrate temperature sensors and adjust settings to ensure consistent production conditions.

11. Inconsistent Resin Quality

Problem: Variations in the quality of polypropylene resin can affect the properties of the fibrillated yarn, leading to inconsistencies in the final product.

Solution: Source polypropylene resin from reputable suppliers and ensure that it meets the required quality standards. Implement quality control measures to test the resin before use. Consistent resin quality is essential for producing reliable and high-quality yarn.

12. Improper Storage Conditions

Problem: Incorrect storage conditions for the yarn or raw materials can lead to issues such as degradation or contamination.

Solution: Store PP fibrillated yarn and raw materials in a clean, dry environment with controlled temperature and humidity. Use proper packaging to protect the yarn from dust, moisture, and other contaminants. Implement inventory management practices to ensure that materials are used within their recommended shelf life.

13. Inadequate Quality Control

Problem: Lack of adequate quality control can result in undetected issues that affect the performance and quality of the yarn.

Solution: Implement a comprehensive quality control system that includes regular inspections and testing of the yarn at various stages of production. Develop standard operating procedures for quality control and ensure that all staff are trained to identify and address potential issues.

14. Inconsistent Winding Tension

Problem: Inconsistent winding tension during the manufacturing process can lead to issues such as uneven yarn tension and reduced quality.

Solution: Adjust the winding equipment to ensure consistent tension throughout the winding process. Regularly check and calibrate the winding machinery to maintain proper tension settings. Monitor the winding process closely to identify and correct any issues promptly.

15. Difficulty in Yarn Handling

Problem: Handling PP fibrillated yarn can be challenging due to its fibrillated nature, leading to issues such as tangling or difficulty in processing.

Solution: Train staff in proper handling techniques to minimize tangling and damage. Use appropriate handling equipment and tools designed for fibrillated yarn. Implement procedures to ensure that the yarn is handled gently and stored correctly to prevent issues during processing.

Conclusion

PP fibrillated yarn is a valuable material with a wide range of applications, but its manufacturing process can present various challenges. By understanding and addressing common issues such as inconsistent yarn thickness, poor fibrillation quality, and yarn fraying, manufacturers can improve the quality and efficiency of their production processes. Implementing robust quality control measures, optimizing equipment settings, and Fibrillated Polypropylene Yarn storage conditions are essential for troubleshooting and resolving these issues. With careful attention to these factors, manufacturers can ensure the production of high-quality PP fibrillated yarn that meets the needs of their customers and applications.

Frequently Asked Questions (FAQs):

1. What steps does Singhal Industries take to address inconsistent yarn thickness in PP fibrillated yarn?

At Singhal Industries, we ensure consistent yarn thickness by closely monitoring the extrusion process and regularly calibrating our equipment. We maintain precise control over temperature, pressure, and extrusion speed to achieve uniform results. Additionally, our quality control team performs frequent inspections to identify and rectify any deviations in thickness, ensuring that our PP fibrillated yarn meets the highest standards of consistency and quality.

2. How does Singhal Industries ensure the quality of fibrillation in its PP yarn products?

Singhal Industries is committed to producing high-quality PP fibrillated yarn by optimizing our fibrillation process. We carefully control the fibrillation parameters, including pressure and temperature, to achieve the desired quality. Our state-of-the-art fibrillation equipment is regularly maintained and calibrated to ensure efficient and effective fibrillation. This rigorous approach allows us to produce yarn with excellent fibrillation quality, enhancing its performance in various applications.

3. What measures does Singhal Industries implement to prevent yarn fraying and breakage during production?

To prevent yarn fraying and breakage, Singhal Industries implements several key measures. We carefully manage yarn tension during production and ensure that all machinery is properly adjusted and maintained. Regular inspections of our equipment help identify and address any potential issues before they affect the yarn. Additionally, our team is trained to handle the yarn with care, minimizing the risk of damage and ensuring that the final product meets our stringent quality standards.

- Questions and Answers

- Opinion

- Story/Motivational/Inspiring

- Technology

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News

- Culture

- War machines and policy