High-Density Polyethylene (HDPE) sheets are a staple in various industries due to their exceptional durability, versatility, and cost-effectiveness. From construction to manufacturing, these sheets offer a range of benefits that make them an attractive choice for many applications. In this blog, we will delve into what Hdpe sheet manufacturer in India are, their diverse applications, advantages, and future trends.

What Are HDPE Sheets?

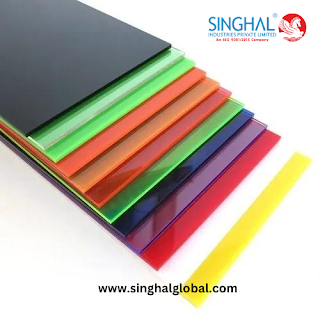

HDPE sheets are made from high-density polyethylene, a type of plastic known for its strength and resistance to various environmental factors. Polyethylene is a polymer that comes in several densities, with HDPE being one of the most robust and versatile forms. HDPE sheets are created through a process that involves melting polyethylene pellets and forming them into thin, Hdpe sheet manufacturers and supplier. These sheets are then cooled and cut into various sizes to meet different needs.

The unique properties of HDPE sheets make them suitable for a wide range of applications. They are characterized by their high strength-to-density ratio, which contributes to their durability and resistance to impact, chemicals, and moisture.

Common Applications of HDPE Sheets

1. Construction and Building

In the construction industry, HDPE sheets are used for a variety of purposes:

-

Building Facades: HDPE sheets are used in building facades for their weather resistance and aesthetic appeal. They can be customized to fit different designs and provide a modern look to buildings.

-

Waterproofing Membranes: HDPE sheets serve as effective waterproofing membranes for foundations, roofs, and other structures. Their resistance to moisture and chemicals makes them ideal for protecting buildings from water damage.

-

Geotechnical Applications: These sheets are used in geotechnical applications such as lining for landfills and containment systems. Their durability and resistance to environmental conditions make them suitable for these demanding uses.

2. Manufacturing and Industrial Uses

HDPE sheets are also prevalent in manufacturing and industrial settings:

-

Machinery Components: The sheets are used to manufacture various machinery components, including liners, wear plates, and guides. Their strength and wear resistance contribute to the longevity of these parts.

-

Fabrication and Prototyping: HDPE sheets are employed in fabrication and prototyping processes due to their ease of machining and cutting. They can be shaped into complex designs and used for creating prototypes and custom parts.

-

Packaging: In the industrial sector, HDPE sheets are used for packaging applications such as pallet liners and protective barriers. Their durability helps ensure that products are protected during storage and transportation.

3. Agriculture and Horticulture

In agriculture and horticulture, HDPE sheets offer several benefits:

-

Greenhouse Covers: HDPE sheets are used as greenhouse covers due to their ability to filter UV light and provide insulation. They help create optimal growing conditions for plants while protecting them from harsh weather.

-

Pond Liners: The sheets are used as pond liners to prevent water loss and contamination. Their resistance to chemicals and UV radiation makes them suitable for lining ponds and water features.

-

Farm Equipment: HDPE sheets are used in various farm equipment, including troughs, tanks, and feeders. Their resistance to impact and weather conditions contributes to the durability and functionality of these items.

4. Transportation and Logistics

In the transportation and logistics industry, HDPE sheets are utilized for:

-

Pallets and Containers: HDPE sheets are used to manufacture pallets and containers that are resistant to moisture, chemicals, and impact. These products are essential for efficient and safe handling of goods during transportation.

-

Protective Barriers: The sheets are used as protective barriers in warehouses and shipping facilities. They help safeguard products from damage and contamination during handling and storage.

Advantages of HDPE Sheets

1. Durability and Strength

One of the key advantages of HDPE sheets is their durability. They are resistant to impact, abrasion, and wear, making them suitable for demanding applications. The high-density nature of the polyethylene contributes to their strength and longevity.

2. Chemical Resistance

HDPE sheets are highly resistant to chemicals, including acids, alkalis, and solvents. This makes them ideal for use in environments where exposure to harsh chemicals is a concern, such as in industrial and agricultural applications.

3. Moisture Resistance

The sheets are resistant to moisture and water, which prevents them from degrading or becoming damaged when exposed to wet conditions. This property makes them useful in applications such as waterproofing and pond lining.

4. Ease of Fabrication

HDPE sheets are relatively easy to fabricate and machine. They can be cut, drilled, and shaped using standard tools, allowing for customization and precise fitting in various applications.

5. Lightweight

Despite their strength, HDPE sheets are lightweight, which makes them easier to handle and transport. This feature is particularly beneficial in applications where weight is a consideration, such as in construction and transportation.

6. Cost-Effectiveness

HDPE sheets offer a cost-effective solution for many applications. Their durability and longevity reduce the need for frequent replacements, leading to long-term savings.

Environmental Considerations

While HDPE sheets offer numerous benefits, it is important to consider their environmental impact:

1. Plastic Waste

As with other plastic products, HDPE sheets contribute to plastic waste if not properly managed. Proper disposal and recycling are essential to minimize environmental impact.

2. Recycling

HDPE is a recyclable material, and many recycling programs accept HDPE products. However, the recycling process can vary depending on local facilities and regulations.

3. Sustainable Practices

To address environmental concerns, manufacturers and consumers should focus on recycling programs and sustainable practices. This includes using recycled HDPE in new products and supporting initiatives that promote responsible plastic use.

Future Trends and Innovations

The future of HDPE sheets involves several exciting trends and innovations:

1. Sustainable Materials

Research into more sustainable materials and manufacturing processes is ongoing. This includes the development of biodegradable or more eco-friendly alternatives to traditional HDPE.

2. Advanced Manufacturing Techniques

Advancements in manufacturing technology may lead to improvements in the properties and performance of HDPE sheets. Innovations could include enhanced strength, flexibility, and functionality.

3. Increased Recycling

Efforts to improve recycling processes and increase the percentage of recycled HDPE in new products are expected to continue. Enhanced recycling methods can help reduce waste and support environmental sustainability.

4. Expanded Applications

As industries seek more versatile and sustainable solutions, the applications for HDPE sheets are likely to expand. New uses and markets may emerge, driven by ongoing demand for durable and cost-effective materials.

Conclusion

HDPE sheets are a versatile and valuable material used across various industries for their durability, chemical resistance, and cost-effectiveness. From construction and manufacturing to agriculture and transportation, these sheets offer practical solutions for a wide range of applications. While addressing environmental concerns is crucial, ongoing innovations and sustainable Hdpe sheets 4x8 manufacturer are paving the way for a more eco-friendly future. As industries continue to evolve and seek efficient materials, HDPE sheets will remain a key component in meeting diverse needs while contributing to environmental stewardship.

Frequently Asked Questions (FAQs):

How does Singhal Industries ensure the durability and strength of their HDPE sheets?

Singhal Industries guarantees the durability and strength of their HDPE sheets by utilizing high-quality polyethylene materials and advanced manufacturing processes. The sheets are produced with a focus on robustness, ensuring they can withstand impact, abrasion, and various environmental conditions. Singhal Industries employs rigorous quality control measures to ensure that each sheet meets the highest standards of performance and longevity.

What environmental measures does Singhal Industries take regarding their HDPE sheets?

Singhal Industries is committed to addressing environmental concerns by focusing on recycling and sustainable practices. They promote the use of recycled HDPE in their products and support recycling programs to minimize plastic waste. Additionally, Singhal Industries is actively exploring more sustainable materials and manufacturing methods to reduce the environmental impact of their HDPE sheets while contributing to broader environmental stewardship efforts.

Why are Singhal Industries' HDPE sheets preferred across various industries despite environmental concerns?

Singhal Industries' HDPE sheets are favored for their exceptional durability, chemical resistance, and cost-effectiveness, making them ideal for a wide range of applications. The sheets provide reliable performance in demanding environments, which is a significant factor in their widespread use. Despite environmental concerns, Singhal Industries balances the benefits of their HDPE sheets with a commitment to sustainable practices and recycling initiatives, ensuring that their products meet practical needs while supporting environmental responsibility.