HDPE T-Rib Liner Sheets have emerged as a crucial solution for industries requiring advanced protection from corrosive environments, water seepage, and chemical exposure. As infrastructure continues to grow and develop, the need for materials that offer durability and resistance to degradation has become more pressing. These liner sheets, made from high-density polyethylene (HDPE), provide a reliable barrier to protect concrete structures and other materials from environmental threats.

HDPE T-Rib Liner Sheets are widely used in sectors such as construction, mining, and wastewater management. Their unique T-rib design ensures that they bond tightly to surfaces like concrete, making them indispensable in protecting infrastructure from deterioration. In this article, we Mahira Polyglobal LLP delve into the various benefits of HDPE T Rib Liner Manufacturer, their diverse applications, and address common questions about their use.

What Are HDPE T-Rib Liner Sheets?

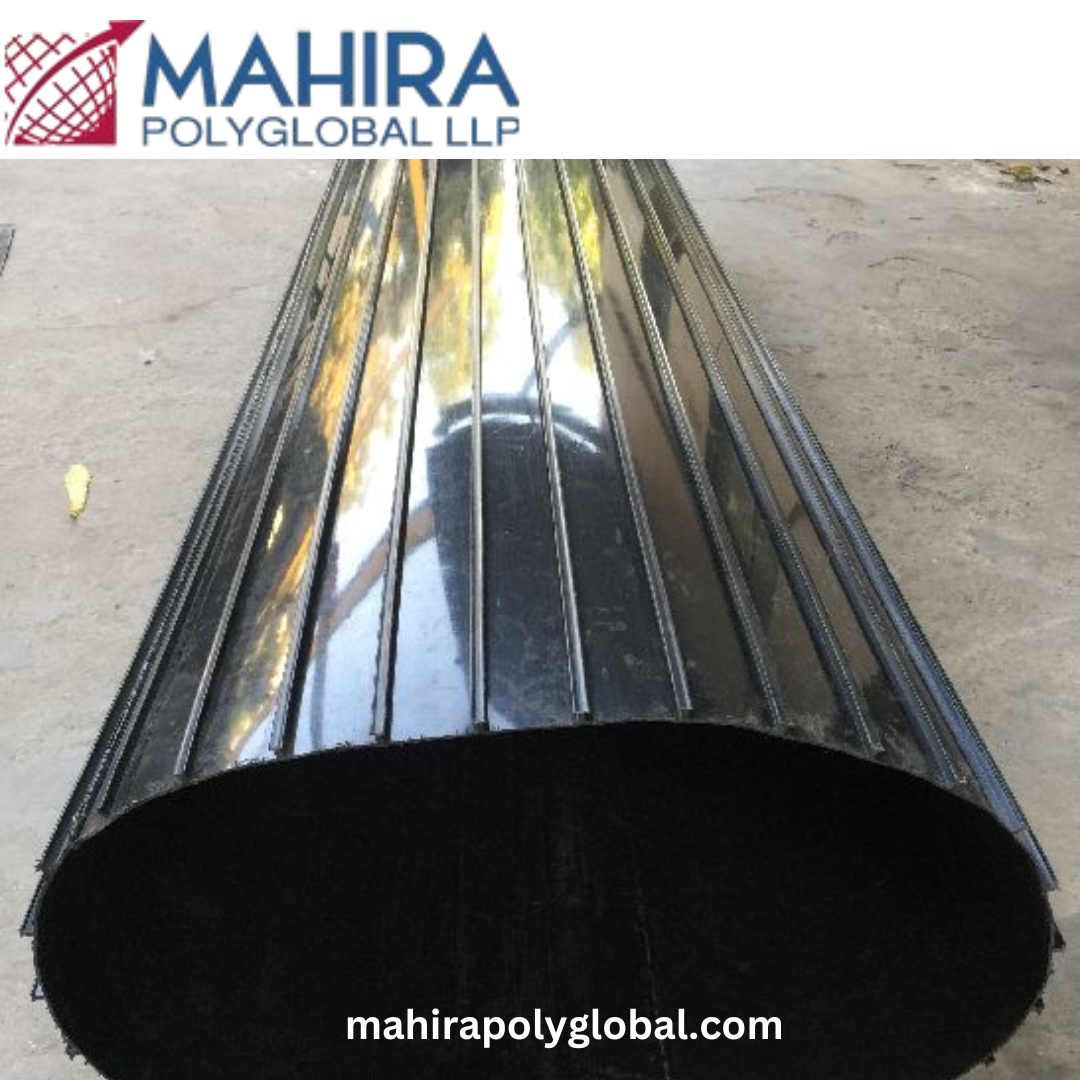

HDPE T-Rib Liner Sheets are made from high-density polyethylene, known for its exceptional resistance to chemicals, moisture, and abrasion. What sets these liner sheets apart is the presence of T-shaped ribs on one side of the sheet, which serve as anchoring points when applied to surfaces like concrete. The ribs ensure that the liner adheres securely to the structure, providing a robust and long-lasting protective layer.

This liner is commonly used in environments where concrete or other structures are exposed to aggressive elements, such as chemicals, corrosive liquids, or moisture. The T-ribbed design is critical in ensuring a tight bond, preventing the liner from peeling or shifting over time, even under harsh conditions.

Key Benefits of HDPE T-Rib Liner Sheets

-

Superior Chemical Resistance

One of the most important features of HDPE T-Rib Liner Sheets is their ability to resist a wide range of chemicals. Industries that deal with acids, alkalis, and other corrosive substances can benefit greatly from the protective qualities of these liners. This makes them ideal for applications in chemical processing plants, wastewater treatment facilities, and mining operations. -

Excellent Waterproofing

HDPE T-Rib liners are highly effective at preventing water from seeping into structures. They provide a waterproof barrier, safeguarding the underlying material from moisture damage. Whether used in tunnels, water tanks, or sewage systems, the liner ensures that water does not compromise the integrity of the structure. -

Durability and Longevity

HDPE is renowned for its toughness and resilience. These liners can endure high levels of stress, including exposure to rough environments, without wearing down. As a result, HDPE T-Rib Liner Sheets are a long-term solution, capable of lasting for decades with minimal maintenance, saving both time and money. -

Strong Bonding Capability

The T-rib design of the liner sheets allows for a secure bond with concrete and other materials. The ribs penetrate the concrete surface, ensuring that the liner stays in place even when exposed to challenging conditions such as vibrations, heavy loads, or movement. This minimizes the risk of delamination or detachment. -

Flexibility and Adaptability

HDPE T-Rib liners are flexible and can easily conform to different surface contours and shapes, making them versatile for a range of applications. From lining curved tunnel walls to sealing irregularly shaped tanks, these liners can adapt to the specific requirements of each project. -

Low Maintenance

Once installed, HDPE T-Rib Liner Sheets require very little maintenance. Their chemical and water resistance means they don’t degrade easily, allowing the structures they protect to last longer without the need for frequent repairs or replacements. -

Cost-Effective

The long lifespan and durability of HDPE T-Rib liners make them a cost-effective solution. While the initial investment might be higher compared to traditional liners, the reduced need for maintenance and replacement over time results in significant savings.

Applications of HDPE T-Rib Liner Sheets

The T-Rib HDPE Liner Sheets India are used in a wide variety of industries and applications due to their protective properties. Below are some of the most common uses:

-

Sewage Treatment Plants

Sewage systems expose concrete and metal structures to a corrosive mix of chemicals and biological materials. HDPE T-Rib liners provide a protective shield, preventing damage to these systems and extending their operational life. -

Tunnels and Underground Structures

HDPE T-Rib liners are frequently used in tunnel construction to prevent water ingress and protect against chemical damage. These liners ensure that tunnels remain safe and structurally sound by preventing moisture from penetrating the concrete walls and floors. -

Water Reservoirs and Storage Tanks

Water storage systems need to be both waterproof and resistant to chemical reactions. HDPE T-Rib Liner Sheets provide excellent protection in these environments, ensuring that water or other stored liquids do not compromise the structure. -

Mining and Industrial Applications

Mining operations often expose materials to harsh chemicals and abrasive substances. HDPE T-Rib liners are used to line processing tanks, containment areas, and pipelines to prevent corrosion and maintain structural integrity in extreme conditions. -

Chemical Storage Tanks

In industries that store or handle aggressive chemicals, HDPE T-Rib liners are essential for protecting storage tanks from corrosive reactions. They ensure that the tanks remain intact and prevent leaks that could be hazardous to both the environment and personnel. -

Dams and Spillways

Dams and spillways require strong waterproofing and erosion protection. HDPE T-Rib liners are often applied in these areas to provide a secure barrier against water pressure and movement, preserving the structure’s integrity over time.

How to Install HDPE T-Rib Liner Sheets

The installation of HDPE T-Rib liner sheets must be done carefully to ensure optimal performance. Here is a general overview of the installation process:

-

Surface Preparation

Before installing the liner, the concrete or surface area must be cleaned thoroughly. Any dirt, dust, or contaminants that could interfere with adhesion must be removed. -

Positioning the Liner

The HDPE T-Rib liner is placed on the prepared surface with the T-ribs facing the concrete. The ribs will anchor into the surface during installation, ensuring a tight fit. -

Welding and Seaming

Seams between the liner sheets must be welded together to create a continuous, leak-proof barrier. This is done using specialized equipment to ensure the seams are strong and waterproof. -

Inspection and Testing

Once the liner is installed, a thorough inspection should be conducted to ensure that there are no weak points or gaps in the liner. Testing may include applying water or other liquids to verify that the liner is leak-proof and properly sealed.

Conclusion

The HDPE T-Rib Liner Sheets Installation are an advanced solution for industries that require durable, chemically resistant, and waterproof barriers to protect their infrastructure. Their T-rib design ensures secure bonding to surfaces like concrete, while their chemical and mechanical resistance make them suitable for a wide range of applications. From sewage treatment plants to mining facilities, HDPE T-Rib liners provide long-lasting protection, saving both time and money in maintenance and repairs. For any project requiring reliable structural protection, these liner sheets are a valuable investment.

Frequently Asked Questions (FAQs)

1. What are HDPE T-Rib Liner Sheets made of?

HDPE T-Rib Liner Sheets are made from high-density polyethylene, a durable and chemically resistant plastic. The T-shaped ribs on one side of the sheet help anchor it securely to concrete or other surfaces.

2. What are the key benefits of HDPE T-Rib Liner Sheets?

These liners offer numerous benefits, including chemical resistance, waterproofing, durability, strong bonding, flexibility, and low maintenance. They are designed for long-term protection in harsh environments.

3. Where are HDPE T-Rib Liner Sheets commonly used?

HDPE T-Rib liners are widely used in wastewater treatment plants, tunnels, water reservoirs, chemical storage tanks, and industrial facilities where chemical resistance and waterproofing are essential.