HDPE Sheets: A Complete Guide to HDPE Plastic Sheets

High-Density Polyethylene (HDPE) sheets are one of the most versatile and widely used materials in various industries today. Known for their strength, durability, and adaptability, HDPE plastic sheets have become a staple in construction, packaging, manufacturing, and countless other sectors. Whether you're looking for a material to build outdoor structures, line ponds, or create durable packaging, HDPE sheets offer a cost-effective and reliable solution.

In this blog, we will explore what HDPE sheets are, their properties, applications, advantages, and how they compare to other materials. By the end, you'll have a comprehensive understanding of why Polyethylene sheet price have become the go-to choice for professionals in numerous fields.

What Are HDPE Sheets?

HDPE sheets are made from High-Density Polyethylene, a thermoplastic polymer known for its high strength-to-density ratio. While polyethylene comes in various forms, HDPE is specifically valued for its toughness, chemical resistance, and low moisture absorption. Plastic sheet hdpe are solid, durable, and flexible, making them ideal for a wide range of applications.

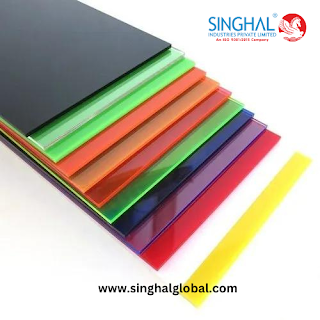

These sheets are typically available in different thicknesses, colors, and sizes, depending on the intended use. They are produced through a process called extrusion, where molten HDPE is shaped into thin sheets. Once cooled, the sheets retain their shape and exhibit a variety of beneficial properties, such as weather resistance and impact strength.

Key Properties of HDPE Sheets

HDPE plastic sheets possess several properties that make them stand out from other materials. These properties contribute to their widespread use across industries:

-

Durability: HDPE sheets are incredibly strong and can withstand significant wear and tear. Their high impact resistance makes them an excellent choice for outdoor and heavy-duty applications.

-

Chemical Resistance: HDPE is resistant to most chemicals, including acids, solvents, and bases. This makes it suitable for use in environments where exposure to harsh chemicals is common.

-

Moisture Resistance: HDPE has a very low moisture absorption rate, making it ideal for applications where water exposure is frequent, such as in marine and agricultural industries.

-

UV Resistance: HDPE sheets can be treated with UV stabilizers, which make them resistant to degradation caused by prolonged exposure to sunlight. This feature is essential for outdoor applications like playground equipment, fencing, and outdoor storage.

-

Lightweight: Despite its strength, HDPE is lightweight, making it easy to transport and handle during installation.

-

Malleability: HDPE sheets are flexible, allowing them to be easily molded or shaped into various forms without cracking or breaking.

-

Recyclability: HDPE is fully recyclable, which makes it an environmentally friendly material. Used HDPE sheets can be melted down and reformed into new products, reducing plastic waste.

-

Non-Toxic: HDPE is considered food-safe and is commonly used for food packaging, cutting boards, and containers, ensuring no harmful chemicals leach into food products.

Common Applications of HDPE Sheets

HDPE sheets are used across a wide range of industries due to their durability and versatility. Here are some of the most common applications:

1. Construction and Building Materials

HDPE sheets are often used in construction projects due to their ability to withstand harsh conditions. They are used as liners for ponds, landfills, and reservoirs because of their impermeability and chemical resistance. Additionally, HDPE sheets are used to create protective barriers, waterproofing layers, and ground stabilization solutions in construction sites.

2. Packaging Industry

The packaging industry relies heavily on HDPE sheets for producing rigid containers, bottles, and packaging materials. Their chemical resistance makes them ideal for storing liquids, chemicals, and food products. HDPE is also used in the production of plastic bags, pallets, and shrink wraps.

3. Agriculture

In agriculture, HDPE sheets are used for a variety of purposes, including lining irrigation canals, building greenhouses, and constructing compost bins. Their resistance to water and chemicals makes them ideal for creating agricultural equipment and structures that need to withstand tough environmental conditions.

4. Marine Industry

Due to their excellent moisture resistance, HDPE sheets are widely used in the marine industry. They are employed in boat construction, docks, and even as liners for fish ponds. Their lightweight nature also makes them easy to handle during installation in marine environments.

5. Playground Equipment

HDPE sheets are commonly used to manufacture playground equipment because they are safe, non-toxic, and resistant to extreme weather conditions. These sheets can be shaped into different colors and designs, making them an attractive choice for outdoor recreational areas.

6. Automotive and Industrial Uses

The automotive and industrial sectors use HDPE sheets for a variety of applications, such as in fuel tanks, chemical storage containers, and automotive components. Their ability to resist impact and chemical exposure makes them an ideal material for these demanding environments.

Advantages of HDPE Sheets Over Other Materials

HDPE sheets offer several advantages over other materials like wood, metal, and other plastics. Here’s how they compare:

1. Compared to Wood

HDPE is far more durable than wood, especially in outdoor environments. Wood is prone to rotting, warping, and insect damage, whereas HDPE sheets are impervious to moisture and pests. Additionally, HDPE does not require regular maintenance like painting or staining, making it a more cost-effective option in the long run.

2. Compared to Metal

While metal is known for its strength, it can corrode and rust over time, particularly in environments exposed to moisture or chemicals. HDPE, on the other hand, does not corrode, making it a better choice for outdoor and marine applications. Moreover, HDPE is much lighter than metal, making transportation and installation easier and less expensive.

3. Compared to Other Plastics

When compared to other plastics like PVC or polypropylene, HDPE stands out due to its higher strength and better impact resistance. HDPE also has superior chemical resistance, making it suitable for harsher industrial and chemical environments.

How to Choose the Right HDPE Sheets

When selecting HDPE sheets for your project, consider the following factors to ensure you choose the right type for your needs:

-

Thickness: HDPE sheets come in a variety of thicknesses, ranging from thin, flexible sheets to thick, rigid ones. The thickness you need will depend on the application. For instance, thicker sheets are ideal for heavy-duty construction or industrial uses, while thinner sheets are suitable for packaging or light-duty applications.

-

UV Resistance: If your project involves outdoor applications, make sure to choose HDPE sheets with UV stabilizers. These additives protect the material from sun damage, extending its lifespan.

-

Color and Finish: HDPE sheets are available in various colors and finishes, which can be important for aesthetic purposes. For example, colored HDPE sheets are often used in playground equipment or outdoor signage.

-

Perforation and Customization: Some applications may require HDPE sheets to be perforated or customized to specific sizes. Many manufacturers offer custom fabrication services to tailor HDPE sheets to your exact specifications.

Installation and Maintenance of HDPE Sheets

HDPE sheets are relatively easy to install and require minimal maintenance. For installation, HDPE sheets can be cut and shaped using standard tools such as saws and drills. Their lightweight nature makes handling easier during the installation process, whether you're lining a pond or constructing a greenhouse.

As for maintenance, HDPE sheets require very little upkeep. They can be cleaned using mild soap and water, and because of their chemical resistance, they won’t degrade when exposed to common cleaning agents. For outdoor applications, periodic cleaning may be necessary to remove dirt and debris, but overall, HDPE is a low-maintenance material.

Conclusion

HDPE sheets are a versatile, durable, and cost-effective material that has become essential in a variety of industries. From construction and agriculture to packaging and playground equipment, HDPE plastic sheets offer unmatched strength, chemical resistance, and adaptability. Their ability to withstand harsh conditions, combined with their low maintenance Hdpe plastic sheet, makes them an ideal choice for both large-scale industrial projects and everyday household applications.

Whether you're looking for a material that can handle tough environmental conditions or something that is safe for food packaging, HDPE sheets are an excellent option. With their long lifespan and recyclability, HDPE sheets are not only a practical choice but also an environmentally friendly one.

Frequently Asked Questions (FAQs):

FAQ 1: Why are Singhal Industries' HDPE sheets considered a durable option?

Singhal Industries' HDPE sheets are known for their exceptional durability due to their high strength-to-density ratio. These sheets are resistant to wear and tear, making them ideal for applications in construction, packaging, and outdoor projects. They can withstand harsh environmental conditions like extreme weather, moisture, and chemical exposure without degrading. This durability ensures long-lasting performance, even in demanding industries such as agriculture and marine environments.

FAQ 2: How are Singhal Industries' HDPE sheets beneficial for outdoor applications?

Singhal Industries' HDPE sheets are well-suited for outdoor applications because of their UV resistance and low moisture absorption. Treated with UV stabilizers, these sheets can resist the damaging effects of prolonged sun exposure, making them perfect for outdoor structures such as playground equipment, fences, and boat components. Additionally, their impermeability to water ensures they won't warp or rot when exposed to moisture, making them an excellent choice for applications like pond liners or irrigation systems.

FAQ 3: Can Singhal Industries' HDPE sheets be customized for specific projects?

Yes, Singhal Industries offers customization options for their HDPE sheets to meet the specific needs of various projects. Customers can choose different thicknesses, colors, and finishes, depending on the application. Whether you need thicker sheets for heavy-duty industrial use or thinner ones for packaging purposes, Singhal Industries can provide tailored solutions. They also offer services like perforation and custom fabrication to ensure the HDPE sheets fit your project's exact requirements.

- Questions and Answers

- Opinion

- Story/Motivational/Inspiring

- Technology

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News

- Culture

- War machines and policy