High-Density Polyethylene (HDPE) sheets have gained immense popularity across various industries due to their durability, strength, and versatility. These plastic sheets are made from thermoplastic polymer, which offers numerous benefits, making them a go-to material for a wide range of applications. Whether used in industrial, agricultural, or domestic settings, Polyethylene sheet price have proven to be one of the most reliable materials in the modern world. This blog will explore the properties, uses, and advantages of HDPE sheets in detail.

What are HDPE Sheets?

HDPE (High-Density Polyethylene) is a type of plastic known for its high strength-to-density ratio. It is derived from petroleum and is one of the most commonly used plastics. HDPE sheets are created by molding HDPE resin into flat, durable panels. These sheets are resistant to impacts, chemicals, and moisture, making them suitable for a wide range of environments and uses.

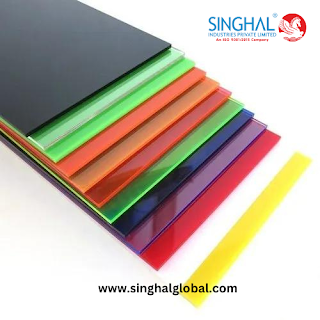

The unique properties of HDPE sheets make them ideal for use in industries such as construction, agriculture, Plastic sheet hdpe, and even medical fields. The versatility and adaptability of HDPE plastic sheets allow them to be customized in various thicknesses, sizes, and colors, depending on the application.

Key Properties of HDPE Sheets

HDPE sheets are favored due to several key properties:

1. Durability

HDPE sheets are highly durable and resistant to wear and tear. This makes them ideal for outdoor applications where materials are exposed to extreme weather conditions, UV rays, and heavy loads. The sheets can withstand impacts without cracking or breaking, making them a long-lasting solution.

2. Lightweight

Despite their durability, HDPE sheets are surprisingly lightweight. This makes them easy to transport, handle, and install. Their lightweight nature also helps reduce the overall cost of transportation and labor during installation.

3. Moisture Resistance

One of the standout features of HDPE sheets is their resistance to moisture. Unlike some other plastics, HDPE sheets do not absorb water, making them perfect for use in environments with high humidity or where the sheets will be in direct contact with water. This property makes them popular in marine applications and for lining ponds or water tanks.

4. Chemical Resistance

HDPE sheets are highly resistant to chemicals, including acids, solvents, and other corrosive substances. This property makes them ideal for use in industrial environments where exposure to harsh chemicals is common.

5. UV Resistance

HDPE sheets are resistant to ultraviolet (UV) light, meaning they do not degrade when exposed to sunlight for extended periods. This makes them ideal for outdoor applications such as playground equipment, fences, and signs.

6. Eco-Friendly

HDPE is an eco-friendly material. It is 100% recyclable, meaning that HDPE sheets can be reused, reducing their impact on the environment. In addition, the production of HDPE generates less harmful emissions compared to other types of plastic, contributing to a more sustainable world.

Common Uses of HDPE Sheets

HDPE sheets are used in a wide variety of industries due to their versatility and durability. Below are some of the most common applications:

1. Construction Industry

In the construction industry, HDPE sheets are used for applications such as temporary fences, barriers, and partitions. They are also commonly used as liners for landfills, waterproofing foundations, and protecting underground cables and pipelines.

2. Agriculture

HDPE sheets are widely used in agriculture, particularly for lining ponds, canals, and irrigation systems. Their resistance to water and chemicals makes them ideal for agricultural applications where exposure to moisture and fertilizers is common. HDPE sheets are also used for greenhouse covers, providing a long-lasting and durable solution for protecting plants from extreme weather conditions.

3. Packaging

HDPE sheets are used to manufacture various packaging products, such as bottles, containers, and bags. These sheets offer excellent protection against moisture and chemicals, making them suitable for packaging food, chemicals, and pharmaceuticals. Their lightweight nature also makes them an ideal choice for reducing shipping costs in the packaging industry.

4. Marine Applications

HDPE sheets are often used in marine applications due to their excellent moisture resistance and UV protection. They are used for building docks, piers, and even boat components. HDPE sheets are also commonly used as liners for water tanks and reservoirs, ensuring a long-lasting, leak-proof solution.

5. Playground Equipment

HDPE sheets are a popular choice for manufacturing playground equipment, park benches, and outdoor furniture. Their durability, resistance to weathering, and vibrant colors make them ideal for outdoor environments where safety and aesthetics are key considerations.

6. Automotive Industry

In the automotive industry, HDPE sheets are used for manufacturing various components, including fuel tanks, door panels, and interior trim. Their lightweight nature helps reduce the overall weight of vehicles, contributing to improved fuel efficiency.

7. Medical Applications

HDPE sheets are used in the medical field for the production of prosthetics, medical devices, and surgical equipment. Their chemical resistance and durability make them suitable for use in sterile environments where exposure to harsh cleaning agents is common.

Benefits of HDPE Sheets

The widespread use of HDPE sheets across various industries is a testament to their numerous benefits. Below are some of the key advantages of using HDPE sheets:

1. Cost-Effective

HDPE sheets are relatively affordable compared to other materials, making them a cost-effective solution for various applications. Their long lifespan and low maintenance requirements further contribute to their cost-effectiveness.

2. Low Maintenance

HDPE sheets require minimal maintenance. They are resistant to scratches, stains, and chemicals, meaning they do not require frequent cleaning or repairs. This makes them an ideal choice for applications where long-term durability is essential.

3. Customizable

HDPE sheets can be easily customized to meet specific needs. They are available in various thicknesses, colors, and sizes, allowing manufacturers to tailor the sheets to their requirements. Additionally, HDPE sheets can be easily cut, shaped, and welded, making them highly versatile.

4. Environmentally Friendly

As previously mentioned, HDPE is 100% recyclable, making it an environmentally friendly material. The production of HDPE also generates fewer harmful emissions compared to other plastics, further reducing its environmental impact.

5. Impact Resistant

HDPE sheets are highly resistant to impacts and pressure. This makes them ideal for high-stress environments where materials are subjected to heavy loads or frequent use.

6. Weatherproof

Whether it's rain, snow, or extreme sunlight, HDPE sheets are built to withstand all types of weather conditions. Their UV resistance ensures that they do not degrade when exposed to sunlight, and their moisture resistance makes them impervious to water damage.

Conclusion

HDPE sheets have revolutionized numerous industries due to their unmatched durability, versatility, and affordability. Whether used in construction, agriculture, packaging, or even medical applications, HDPE sheets offer a wide range of benefits, from cost-effectiveness to environmental sustainability. Their ability to withstand harsh conditions, chemicals, and moisture ensures that they provide a reliable and long-lasting solution for various applications.

As the world continues to shift toward more sustainable and environmentally friendly materials, Hdpe plastic sheet stand out as a top choice for industries looking to reduce their environmental footprint without compromising on quality and performance. Their adaptability and eco-friendliness make them a valuable material that will continue to play a crucial role in shaping the future of multiple sectors.

In summary, HDPE sheets are more than just plastic—they are a material that combines strength, versatility, and sustainability to meet the diverse needs of modern industries.

Frequently Asked Questions (FAQs):

What are HDPE sheets, and how does Singhal Industries ensure their quality?

HDPE sheets, or High-Density Polyethylene sheets, are durable and versatile plastic sheets known for their high strength and resistance to chemicals, moisture, and UV rays. Singhal Industries manufactures HDPE sheets with stringent quality control measures, ensuring they meet the highest industry standards. Their products are designed to withstand harsh conditions and offer long-lasting performance across various applications, including construction, packaging, and agriculture.

Why should I choose Singhal Industries' HDPE sheets for my project?

Singhal Industries' HDPE sheets offer numerous benefits, including durability, lightweight design, chemical and moisture resistance, and eco-friendliness. The sheets are customizable in different sizes, thicknesses, and colors to suit specific project needs. Whether you need them for construction, packaging, or industrial use, Singhal Industries ensures that their HDPE sheets provide a cost-effective and sustainable solution.

How are Singhal Industries' HDPE sheets environmentally friendly?

Singhal Industries' HDPE sheets are 100% recyclable, making them an environmentally friendly choice for various industries. The production process is designed to minimize harmful emissions, and the sheets can be repurposed after use. This focus on sustainability ensures that choosing HDPE sheets from Singhal Industries supports a greener, more eco-conscious approach to industrial and construction materials.