In the realm of industrial and commercial materials, PP corrugated sheets have emerged as a versatile and valuable solution. Known for their durability, flexibility, and cost-effectiveness, these sheets are widely used across various sectors. Whether you’re new to this material or looking to understand its applications better, this blog will provide a thorough overview of Corrugated sheet price, highlighting their benefits, uses, and reasons why they might be the perfect choice for your next project.

What are PP Corrugated Sheets?

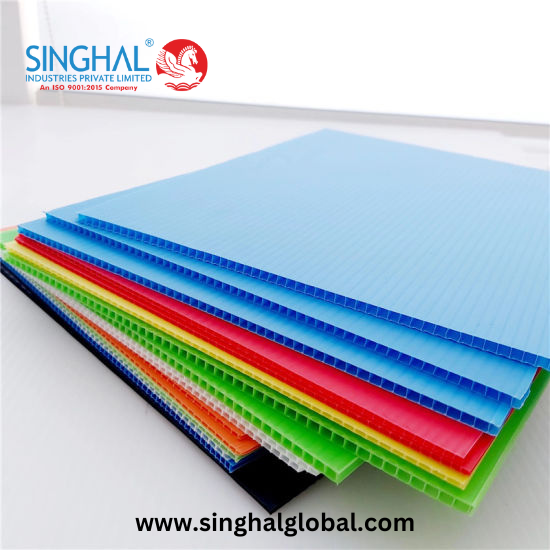

PP corrugated sheets, also known as polypropylene corrugated sheets, are made from polypropylene (PP), a type of plastic. These sheets are characterized by their unique corrugated structure, which consists of a series of parallel ridges and grooves. This design not only enhances the sheet's strength but also makes it lightweight and flexible. The PP corrugated sheet price is produced by extruding polypropylene into a sheet and then creating the corrugations.

Key Benefits of PP Corrugated Sheets

PP corrugated sheets offer numerous advantages that make them a popular choice for various applications. Here are some of the key benefits:

1. Durability and Strength

One of the standout features of PP corrugated sheets is their exceptional durability. The corrugated structure enhances the sheet’s strength, making it resistant to impact, bending, and breaking. This makes PP corrugated sheets ideal for applications where durability is crucial, such as packaging and construction.

2. Lightweight

Despite their strength, PP corrugated sheets are remarkably lightweight. This property makes them easy to handle, transport, and install, reducing labor costs and simplifying the construction or packaging process. Their lightweight nature also contributes to lower shipping costs and easier storage.

3. Weather Resistance

PP corrugated sheets are resistant to various weather conditions, including moisture, UV rays, and extreme temperatures. This makes them suitable for outdoor use and ensures that they will maintain their integrity and appearance even when exposed to the elements. Their resistance to moisture also prevents issues like mold and mildew.

4. Cost-Effectiveness

Compared to other materials, PP corrugated sheets are highly cost-effective. They offer excellent value for money due to their durability and longevity. The low manufacturing and material costs contribute to their affordability, making them an attractive option for budget-conscious projects.

5. Recyclability

PP corrugated sheets are recyclable, which aligns with environmentally friendly practices. After their useful life, these sheets can be reprocessed and reused, reducing waste and promoting sustainability. This makes them a responsible choice for eco-conscious businesses and projects.

6. Ease of Fabrication

PP corrugated sheets can be easily cut, shaped, and fabricated to meet specific requirements. They can be customized to various sizes and forms, allowing for versatility in design and application. This ease of fabrication makes them suitable for a wide range of uses.

Applications of PP Corrugated Sheets

The versatility of PP corrugated sheets means they are used in a variety of applications across different industries. Here are some of the most common uses:

1. Packaging

PP corrugated sheets are widely used in the packaging industry due to their strength and lightweight nature. They are commonly employed to make boxes, containers, and pallets. Their durability ensures that products are protected during transportation and storage, while their recyclability contributes to sustainable packaging solutions.

2. Construction

In the construction industry, PP corrugated sheets are used for a range of purposes. They can serve as temporary barriers, protective covers, or insulation materials. Their resistance to weather conditions makes them suitable for outdoor construction projects, where they can protect building materials and equipment from the elements.

3. Advertising and Signage

The versatility of PP corrugated sheets extends to the advertising and signage sectors. They are used to create durable and weather-resistant signs, banners, and displays. The ability to print vibrant graphics on PP corrugated sheets makes them an effective medium for promotional and informational signage.

4. Agriculture

In agriculture, PP corrugated sheets are utilized for various applications, including as covers for greenhouses and as protective barriers for crops. Their resistance to moisture and UV rays helps maintain a stable environment for plant growth, while their durability ensures long-lasting performance in agricultural settings.

5. Event Management

PP corrugated sheets are also used in event management for creating temporary structures, display panels, and other elements. Their lightweight and durable nature makes them easy to transport and set up, while their customizable features allow for creative and functional event solutions.

Installation and Maintenance

Installing and maintaining PP corrugated sheets is relatively straightforward. Here are some tips to ensure a successful installation and long-term performance:

Installation

- Preparation: Measure and cut the PP corrugated sheets to the required dimensions. Use a utility knife or a saw for precise cutting. Ensure that the surface where the sheets will be installed is clean and dry.

- Mounting: Depending on the application, PP corrugated sheets can be attached using screws, nails, or adhesive. For packaging and construction applications, ensure that the sheets are securely fastened to prevent movement or damage.

- Sealing: If the PP corrugated sheets are used in applications where weather resistance is critical, such as in construction or outdoor signage, consider applying a sealant around the edges to enhance their weatherproofing.

Maintenance

- Cleaning: Regularly clean PP corrugated sheets with water and a mild detergent to remove dirt and debris. Avoid using abrasive cleaners or tools that could damage the surface of the sheets.

- Inspection: Periodically inspect the sheets for any signs of wear, damage, or degradation. Replace any damaged sections to maintain the integrity and functionality of the sheets.

- Storage: Store PP corrugated sheets in a dry, cool place away from direct sunlight to prevent any potential deformation or degradation over time.

Why Choose PP Corrugated Sheets?

Choosing PP corrugated sheets for your project or application offers numerous advantages. Their durability, lightweight nature, weather resistance, and cost-effectiveness make them a practical and versatile choice. Whether you need packaging solutions, construction materials, or advertising displays, PP corrugated sheets provide reliable performance and value.

The ease of fabrication and recyclability of PP corrugated sheets also align with modern sustainability practices, making them a responsible choice for environmentally conscious projects. Their wide range of applications ensures that they can meet various needs across different industries, offering both functionality and aesthetic appeal.

Conclusion

PP corrugated sheets are a valuable material that offers numerous benefits for a wide range of applications. From packaging and construction to signage and agriculture, these sheets provide durability, cost-effectiveness, and versatility. Their lightweight and weather-resistant properties, combined with ease of fabrication and recyclability, make them an ideal choice for various projects. By understanding the advantages and applications of PP corrugated sheet manufacturer, you can make an informed decision for your next project and enjoy the many benefits this material has to offer.

Frequently Asked Questions (FAQs):

1. What makes Singhal Industries’ PP corrugated sheets a durable choice for various applications?

Singhal Industries’ PP corrugated sheets are highly durable due to their unique corrugated design, which enhances their strength and impact resistance. The polypropylene material used in these sheets is designed to withstand harsh conditions, including extreme temperatures, moisture, and UV exposure. This durability ensures that the sheets maintain their structural integrity and performance over time, making them suitable for demanding applications such as packaging, construction, and outdoor signage.

2. How does Singhal Industries’ PP corrugated sheet contribute to cost-effectiveness in projects?

Singhal Industries’ PP corrugated sheets are cost-effective due to their affordability, lightweight nature, and durability. The sheets are priced competitively, which helps reduce material costs. Additionally, their lightweight properties lower shipping and handling expenses. Their long-lasting performance means fewer replacements and repairs, further contributing to overall cost savings. This makes Singhal Industries’ PP corrugated sheets a practical and budget-friendly choice for a variety of projects.

3. In what ways do Singhal Industries’ PP corrugated sheets support environmental sustainability?

Singhal Industries’ PP corrugated sheets support environmental sustainability through their recyclability and long-term durability. The polypropylene material can be recycled, reducing waste and promoting the responsible use of resources. Additionally, the sheets’ durability means that they have a longer lifespan compared to other materials, minimizing the need for frequent replacements and further contributing to sustainability efforts. By choosing Singhal Industries’ PP corrugated sheets, businesses and consumers can support eco-friendly practices while benefiting from a reliable material.