In the diverse world of materials and packaging solutions, PP (Polypropylene) sheets have emerged as a popular choice due to their exceptional durability and versatility. These sheets, made from polypropylene, offer a range of benefits and applications across various industries. In this blog, we'll explore what PP sheet price are, their key features, benefits, and common uses. By the end of this guide, you'll have a comprehensive understanding of why PP sheets are a valuable addition to many commercial and industrial applications.

What Are PP Sheets?

PP sheets are flat panels made from polypropylene, a thermoplastic polymer known for its strength and flexibility. Polypropylene is a type of plastic that is resistant to chemical reactions, moisture, and heat, making it an Polypropylene sheets suppliers for a variety of uses. The sheets are typically produced through extrusion, where molten polypropylene is forced through a die to create thin, uniform sheets.

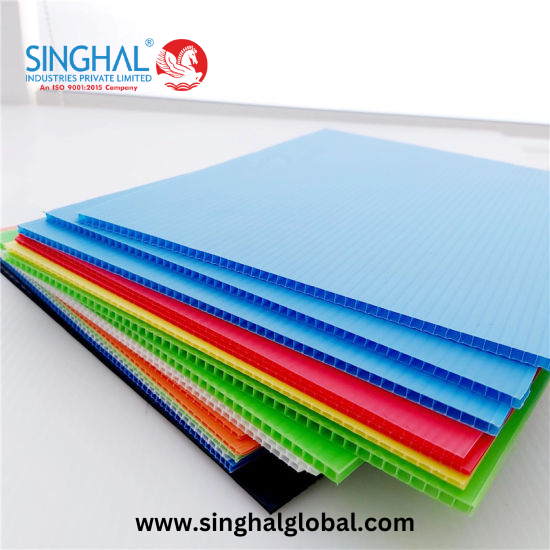

These sheets come in various thicknesses, colors, and finishes, allowing them to be tailored to specific needs. Their lightweight nature and sturdy construction make them suitable for both practical and aesthetic applications.

Key Features of PP Sheets

1. Durability

One of the standout features of PP sheets is their durability. Polypropylene is known for its resistance to wear and tear, making PP sheets strong and long-lasting. They can withstand impact, stress, and various environmental conditions, which is crucial for applications where strength and reliability are paramount.

2. Chemical Resistance

PP sheets exhibit excellent resistance to a wide range of chemicals, including acids, bases, and solvents. This makes them suitable for use in environments where exposure to harsh substances is a concern. Their chemical resistance ensures that they maintain their integrity and performance even in challenging conditions.

3. Moisture Resistance

Polypropylene's low moisture absorption properties make PP sheets resistant to water and humidity. This characteristic is beneficial for applications where moisture exposure could lead to degradation or damage. The moisture resistance of PP sheets helps maintain their structural integrity and extends their lifespan.

4. Lightweight

Despite their strength, PP sheets are relatively lightweight. This feature makes them easy to handle, transport, and install. The lightweight nature of PP sheets also contributes to cost savings in shipping and logistics, as they do not add significant weight to the overall package.

5. Versatility

PP sheets are incredibly versatile and can be used in a wide range of applications. They can be easily cut, shaped, and fabricated to meet specific requirements, making them suitable for various industries and purposes. The versatility of PP sheets extends to their ability to be printed on or laminated, adding to their adaptability.

Benefits of PP Sheets

1. Cost-Effectiveness

PP sheets offer a cost-effective solution for many applications. Their durability and long lifespan reduce the need for frequent replacements, resulting in cost savings over time. Additionally, their lightweight nature helps lower shipping and handling costs, making them an economical choice for businesses.

2. Easy to Fabricate

PP sheets can be easily fabricated into various shapes and sizes, allowing for customization based on specific needs. They can be cut, welded, or thermoformed to create different products, which adds to their flexibility and usability. This ease of fabrication makes PP sheets a popular choice for manufacturing a range of items.

3. Environmental Impact

Polypropylene is a recyclable material, and PP sheets can be recycled at the end of their lifecycle. This contributes to reducing environmental impact and supports sustainability efforts. By choosing recyclable materials, businesses can align with eco-friendly practices and promote responsible waste management.

4. Aesthetic Appeal

PP sheets are available in a variety of colors and finishes, allowing them to be used in applications where appearance is important. The ability to choose from different colors and surface textures enhances their aesthetic appeal, making them suitable for both functional and decorative uses.

5. Thermal Resistance

PP sheets can withstand a range of temperatures, from low to moderately high, without losing their structural integrity. This thermal resistance makes them suitable for applications that involve temperature fluctuations or exposure to heat. Their ability to maintain performance under varying temperature conditions adds to their versatility.

Applications of PP Sheets

1. Packaging

In the packaging industry, PP sheets are used for creating packaging solutions such as containers, trays, and dividers. Their durability and moisture resistance make them ideal for protecting products during transportation and storage. Additionally, their lightweight nature helps reduce shipping costs, making them an efficient packaging material.

2. Signage and Displays

PP sheets are commonly used for signage and display applications due to their printability and aesthetic appeal. They can be easily customized with graphics, text, and colors to create eye-catching signs and displays. The ability to withstand outdoor conditions and maintain their appearance over time makes PP sheets a popular choice for this purpose.

3. Industrial Applications

In industrial settings, PP sheets are used for a variety of purposes, including equipment covers, machine guards, and parts. Their chemical resistance and durability make them suitable for harsh environments and challenging applications. The versatility of PP sheets allows them to be adapted for different industrial needs.

4. Automotive Industry

The automotive industry utilizes PP sheets for various components such as interior panels, dashboards, and trim parts. The lightweight nature of PP sheets contributes to fuel efficiency, while their durability and resistance to chemicals ensure long-lasting performance in automotive applications.

5. Construction and Building

In construction, PP sheets are used for applications such as temporary barriers, insulation, and protective covers. Their moisture resistance and durability make them suitable for construction sites where exposure to the elements is a concern. The ease of handling and fabrication adds to their usefulness in building projects.

6. Medical and Healthcare

PP sheets are also used in the medical and healthcare industries for items such as trays, containers, and protective covers. Their chemical resistance and ease of cleaning make them suitable for medical applications where hygiene and sterility are essential.

Choosing the Right PP Sheet

Selecting the appropriate PP sheet involves considering several factors to ensure it meets your specific requirements:

1. Thickness and Size

Determine the thickness and size of the PP sheet based on the intended application. Different thicknesses offer varying levels of strength and durability, so choose one that aligns with your needs.

2. Surface Finish

Consider the surface finish of the PP sheet, as it can affect the appearance and functionality of the final product. Options include glossy, matte, or textured finishes, depending on your preferences.

3. Customization Needs

If customization is important, choose PP sheets that can be easily cut, printed, or fabricated to meet your specific needs. Customization options allow you to tailor the sheets to your exact requirements.

4. Environmental Considerations

Opt for PP sheets that align with your environmental goals. Look for recyclable materials and consider the impact of the sheets on sustainability.

Conclusion

PP sheets offer a versatile and practical solution for a wide range of applications across various industries. Their durability, chemical resistance, and lightweight nature make them a valuable material for packaging, signage, industrial uses, and more. By understanding the features, benefits, and applications of Polypropylene sheets manufacturers, businesses and individuals can make informed decisions and optimize their use of this innovative material.

Whether you need a cost-effective packaging solution, a durable component for industrial use, or an aesthetically pleasing display material, PP sheets provide a reliable and adaptable option. Their ability to meet diverse needs and perform under various conditions underscores their importance in the world of materials and packaging.

Frequently Asked Questions (FAQs):

What makes Singhal Industries' PP sheets a good choice for packaging applications?

Singhal Industries' PP sheets are an excellent choice for packaging applications due to their durability, moisture resistance, and lightweight nature. These sheets are designed to withstand impact and protect products during transportation and storage. Their resistance to moisture ensures that they maintain the integrity of the packaged goods, while their lightweight design helps reduce shipping costs. Additionally, Singhal Industries' PP sheets can be easily customized to meet specific packaging needs, making them a versatile and practical solution.

How does Singhal Industries ensure the quality of their PP sheets?

Singhal Industries ensures the quality of their PP sheets through rigorous quality control processes. Each sheet is manufactured using high-quality polypropylene and undergoes thorough testing to meet industry standards for strength and performance. Singhal Industries' commitment to quality is reflected in their attention to detail throughout the production process, ensuring that their PP sheets deliver consistent durability, chemical resistance, and reliability for various applications.

Can Singhal Industries' PP sheets be customized for specific needs?

Yes, Singhal Industries offers customization options for their PP sheets to suit specific requirements. Customers can choose from various thicknesses, colors, and finishes to match their application needs. Singhal Industries also provides options for custom printing and fabrication, allowing businesses to tailor the sheets to their branding or functional needs. This flexibility ensures that Singhal Industries' PP sheets can be adapted for a wide range of uses across different industries.