PP sheets, or polypropylene sheets, are a popular choice in various industries due to their versatility, durability, and cost-effectiveness. Made from polypropylene, a thermoplastic polymer, these sheets offer a range of benefits that make them suitable for numerous applications. In this blog, we’ll delve into what PP sheet price are, their key features, their diverse uses, and why they might be the ideal material for your needs.

What Are PP Sheets?

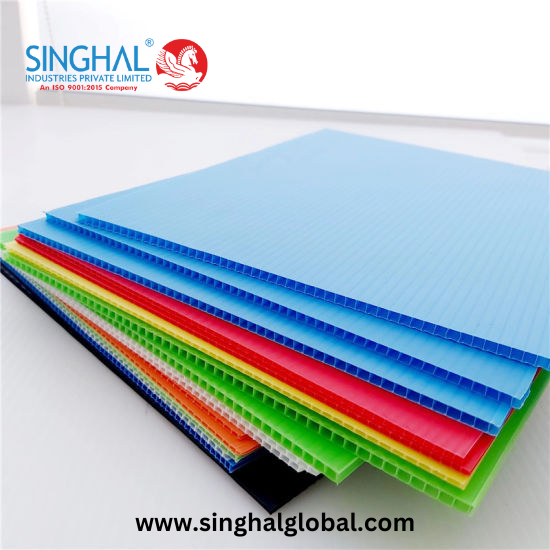

PP sheets are flat, rigid panels made from polypropylene, a type of thermoplastic polymer. Polypropylene is known for its chemical resistance, durability, and versatility, which makes it an excellent material for a wide range of applications. Polypropylene sheets suppliers can be produced in various thicknesses, sizes, and colors, catering to different industrial and commercial needs.

The manufacturing process involves extruding molten polypropylene through a die to form sheets. These sheets are then cooled and cut to the desired dimensions. The result is a strong, lightweight, and flexible material that can be used in numerous applications.

Key Features of PP Sheets

PP sheets are distinguished by several key features that contribute to their widespread use:

1. Durability

One of the standout features of PP sheets is their durability. Polypropylene is known for its resistance to impact and stress, which makes these sheets capable of withstanding heavy use and harsh conditions. This durability is particularly valuable in industrial applications where the material is subjected to constant wear and tear.

2. Chemical Resistance

PP sheets offer excellent resistance to a wide range of chemicals, including acids, alkalis, and solvents. This property makes them suitable for use in environments where exposure to harsh chemicals is common, such as in laboratories, chemical processing plants, and industrial settings.

3. Lightweight

Despite their strength, PP sheets are relatively lightweight. This characteristic makes them easy to handle, transport, and install. The lightweight nature of the sheets also contributes to cost savings in shipping and handling.

4. Flexibility and Versatility

PP sheets are flexible and can be easily cut, shaped, and welded to fit various applications. They can be used for creating custom-sized panels, containers, and enclosures. The versatility of PP sheets makes them suitable for a wide range of industries and purposes.

5. Temperature Resistance

Polypropylene sheets can withstand a range of temperatures, from low to moderately high. They maintain their integrity and performance even in varying temperature conditions, making them suitable for applications where temperature fluctuations are a concern.

6. Cost-Effectiveness

PP sheets are known for their cost-effectiveness. The material is relatively inexpensive to produce, and its long lifespan and durability contribute to lower overall costs. This makes PP sheets a popular choice for businesses looking for affordable and reliable solutions.

Applications of PP Sheets

PP sheets find use in a diverse range of applications across various industries. Here are some common uses:

1. Packaging

In the packaging industry, PP sheets are used to create sturdy and lightweight containers, boxes, and trays. Their durability and resistance to moisture make them ideal for packaging products that need protection during transportation and storage.

2. Industrial and Manufacturing

PP sheets are widely used in industrial and manufacturing settings for creating custom parts, machine covers, and protective barriers. Their chemical resistance and durability make them suitable for environments with exposure to harsh chemicals and mechanical stress.

3. Construction

In construction, PP sheets are used for creating temporary barriers, insulation panels, and protective coverings. Their lightweight and versatile nature make them easy to handle and install, while their resistance to moisture and chemicals adds to their effectiveness in construction applications.

4. Signage and Display

PP sheets are commonly used for creating signage and display materials. Their ability to be easily cut and shaped, combined with their durability, makes them a popular choice for indoor and outdoor signs, banners, and promotional displays.

5. Medical and Healthcare

In the medical and healthcare industries, PP sheets are used for creating trays, containers, and protective covers. Their chemical resistance and ease of sterilization make them suitable for use in environments where hygiene and cleanliness are critical.

6. Automotive

The automotive industry utilizes PP sheets for manufacturing interior panels, trims, and other components. The material’s durability and resistance to impact make it a good fit for various automotive applications.

Advantages of PP Sheets

The benefits of using PP sheets extend beyond their basic features and applications:

1. Enhanced Protection

PP sheets provide excellent protection for a wide range of products and materials. Their resistance to chemicals, moisture, and impact ensures that items packaged or covered with PP sheets remain in good condition during storage and transportation.

2. Easy Processing

PP sheets are easy to process and work with. They can be cut, shaped, and welded to meet specific requirements, making them suitable for custom applications. The ease of processing contributes to their versatility and widespread use.

3. Long Lifespan

The durability and resistance of PP sheets translate into a long lifespan. This longevity reduces the need for frequent replacements, offering both cost and environmental benefits.

4. Environmental Considerations

Polypropylene is a recyclable material, and PP sheets can be recycled at the end of their life cycle. This contributes to more sustainable packaging and manufacturing practices, aligning with environmental goals and reducing waste.

5. Customization Options

PP sheets can be customized to suit various needs. This includes adjusting the thickness, color, and size of the sheets, as well as incorporating specific features such as anti-static properties or UV resistance. Customization allows businesses to tailor the sheets to their unique requirements.

Conclusion

PP sheets are a versatile, durable, and cost-effective solution for a wide range of applications. Their strength, chemical resistance, and lightweight nature make them suitable for use in packaging, industrial settings, construction, signage, medical, and automotive applications. The ability to easily process and customize PP sheets further enhances their appeal.

As industries continue to seek materials that offer both performance and affordability, PP sheets remain a popular choice. Their benefits, combined with their environmentally friendly properties, ensure that they will Polypropylene sheets manufacturers to be a valuable material in various sectors. Whether you need packaging solutions, industrial components, or custom panels, PP sheets provide a reliable and efficient option.

Frequently Asked Questions (FAQs):

Q1: What makes PP sheets from Singhal Industries a reliable choice for industrial applications?

PP sheets from Singhal Industries are known for their exceptional durability and chemical resistance, making them a reliable choice for industrial applications. The polypropylene material used in these sheets ensures that they can withstand harsh conditions and resist damage from chemicals and mechanical stress. This durability is crucial for creating custom parts, machine covers, and protective barriers in industrial settings, where the sheets must endure heavy use and exposure to challenging environments.

Q2: How does Singhal Industries ensure the quality of their PP sheets?

Singhal Industries is committed to maintaining high-quality standards for their PP sheets by using premium-grade polypropylene and adhering to stringent manufacturing processes. The company implements rigorous quality control measures throughout production to ensure that each sheet meets the required specifications for strength, flexibility, and chemical resistance. By focusing on quality at every stage of production, Singhal Industries ensures that their PP sheets deliver reliable performance across various applications.

Q3: What are the environmental benefits of using PP sheets from Singhal Industries?

Singhal Industries emphasizes sustainability in their production of PP sheets. These sheets are made from recyclable polypropylene, contributing to reduced environmental impact. The durability and long lifespan of Singhal Industries' PP sheets also mean fewer replacements are needed, which helps minimize waste. Additionally, the company’s commitment to using recyclable materials aligns with broader environmental goals, supporting eco-friendly practices in packaging and manufacturing.