In the realm of modern materials, polypropylene (PP) sheets have emerged as a versatile and highly useful option for a variety of applications. Known for their durability, flexibility, and resistance to various environmental factors, PP sheets offer numerous benefits across different industries. This blog provides a comprehensive overview of PP sheet price, including their features, advantages, applications, and why they might be the ideal choice for your needs.

What Are PP Sheets?

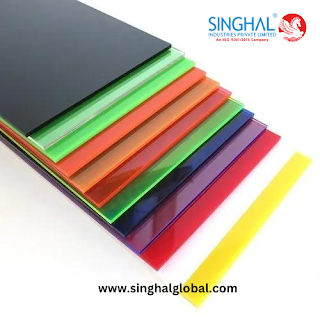

Polypropylene sheets, commonly referred to as PP sheets, are flat, rigid panels made from polypropylene polymer. This thermoplastic material is widely recognized for its strength and chemical resistance. Polypropylene sheets suppliers are available in various thicknesses, sizes, and colors, making them suitable for a wide range of applications.

Features of PP Sheets

PP sheets come with several distinctive features that make them a preferred choice for various uses:

- Durability: PP sheets are known for their toughness and resistance to impact, making them suitable for environments where durability is essential.

- Chemical Resistance: These sheets are resistant to many chemicals, including acids, bases, and solvents, which makes them ideal for use in chemical processing and laboratory settings.

- Flexibility: PP sheets are available in a range of thicknesses and can be easily cut, shaped, or fabricated to meet specific requirements.

- Lightweight: Despite their strength, PP sheets are lightweight, which reduces handling and transportation costs.

- Weather Resistance: PP sheets can withstand exposure to various weather conditions, including UV radiation, making them suitable for outdoor applications.

Benefits of PP Sheets

The use of PP sheets offers several key benefits that contribute to their popularity across different industries:

1. Versatility

PP sheets are incredibly versatile and can be used in a variety of applications. Their ability to be cut, shaped, and fabricated into different forms allows for customization to meet specific needs. Whether you require sheets for industrial, commercial, or residential purposes, PP sheets can be tailored to fit a wide range of applications.

2. Cost-Effectiveness

PP sheets are cost-effective compared to other materials such as metal or glass. Their affordability, combined with their durability and low maintenance requirements, makes them an economical choice for many applications. The lightweight nature of PP sheets also contributes to lower shipping and handling costs.

3. Ease of Fabrication

One of the significant advantages of PP sheets is their ease of fabrication. They can be easily cut, drilled, and shaped using standard tools, allowing for quick and efficient customization. This flexibility in fabrication makes PP sheets a practical choice for various projects, from simple DIY tasks to complex industrial applications.

4. Chemical and Corrosion Resistance

PP sheets exhibit excellent resistance to chemicals and corrosion, making them ideal for use in environments where exposure to harsh substances is a concern. They are commonly used in chemical processing plants, laboratories, and other settings where chemical resistance is crucial.

5. Lightweight and Easy to Handle

Despite their strength and durability, PP sheets are lightweight, which makes them easy to handle and install. This feature is particularly beneficial for applications where weight is a factor, such as in construction or transportation.

Applications of PP Sheets

The versatility of PP sheets means they can be used in a wide range of applications across various industries:

1. Industrial Applications

In industrial settings, PP sheets are used for a variety of purposes, including machine guards, conveyor belts, and protective covers. Their durability and resistance to wear and tear make them suitable for harsh environments where other materials might fail.

2. Chemical Processing

Due to their chemical resistance, PP sheets are commonly used in chemical processing facilities. They are used to line tanks, create containment barriers, and fabricate various components that come into contact with corrosive substances.

3. Packaging

PP sheets are used in packaging applications, including the production of containers, trays, and inserts. Their lightweight nature and durability make them a practical choice for packaging products in various industries, from food and beverages to electronics.

4. Construction

In the construction industry, PP sheets are used for a range of applications, including insulation, roofing, and partitioning. Their weather resistance and ability to be easily cut and shaped make them a versatile material for various construction needs.

5. Signage and Displays

PP sheets are also used in the creation of signage and display panels. Their ability to be easily printed and shaped makes them ideal for producing custom signs, posters, and promotional displays. The durability of PP sheets ensures that these displays remain intact and vibrant even with prolonged exposure to the elements.

Choosing the Right PP Sheets

When selecting PP sheets for your needs, consider the following factors to ensure you choose the best option:

1. Thickness and Size

Determine the appropriate thickness and size of the PP sheets based on the specific requirements of your application. Thicker sheets provide greater strength and durability, while thinner sheets are more flexible and easier to handle.

2. Color and Finish

PP sheets are available in various colors and finishes, including transparent, opaque, and textured options. Choose a color and finish that suits the aesthetic and functional requirements of your project.

3. Fabrication Needs

Consider the fabrication needs of your project. If you require custom cuts or shapes, ensure that the PP sheets you select can be easily fabricated using standard tools and techniques.

4. Environmental Factors

Evaluate the environmental factors that the PP sheets will be exposed to, such as UV radiation, temperature fluctuations, and chemical exposure. Choose sheets that are designed to withstand these conditions and provide the necessary protection.

Conclusion

PP sheets are a versatile and practical material that offers a range of benefits for various applications. Their durability, chemical resistance, and ease of fabrication make them a popular choice across different industries. Whether you are involved in industrial processes, construction, packaging, or signage, PP sheets provide a cost-effective and reliable solution for your needs.

By understanding the features, benefits, and applications of PP sheets, you can make an informed decision that enhances your projects and meets your specific requirements. With their Polypropylene sheets manufacturers of strength, flexibility, and affordability, PP sheets are poised to remain a valuable asset in the world of materials and manufacturing for years to come.

Frequently Asked Questions (FAQs):

FAQ 1:

Why should I choose PP sheets from Singhal Industries for my industrial applications?

Singhal Industries' PP sheets are a top choice for industrial applications due to their exceptional durability and resistance to wear and tear. Made from high-quality polypropylene, these sheets are designed to withstand the rigors of demanding environments. They are also resistant to chemicals and corrosion, making them suitable for use in various industrial settings where exposure to harsh substances is a concern. Singhal Industries' commitment to quality ensures that their PP sheets meet rigorous standards, providing reliable performance for your industrial needs.

FAQ 2:

How does Singhal Industries ensure the quality and reliability of their PP sheets?

Singhal Industries ensures the quality and reliability of their PP sheets through stringent quality control processes and the use of high-grade polypropylene material. Each sheet undergoes rigorous testing to meet industry standards for strength, durability, and chemical resistance. Singhal Industries' focus on maintaining high manufacturing standards guarantees that their PP sheets provide consistent performance and longevity, making them a dependable choice for various applications.

FAQ 3:

What customization options are available for PP sheets from Singhal Industries?

Singhal Industries offers a range of customization options for their PP sheets to meet specific customer needs. You can choose from various thicknesses, sizes, and colors to suit your particular requirements. Additionally, Singhal Industries can accommodate custom fabrication requests, including cutting and shaping the sheets to fit your project. This flexibility allows you to tailor the PP sheets to your exact specifications, ensuring they meet the functional and aesthetic needs of your application.