How Performance Additives Are Shaping Modern Manufacturing

Performance additives are revolutionizing modern manufacturing by enhancing the quality, functionality, and durability of products across various industries. As manufacturers strive to meet rising consumer expectations and navigate complex operational challenges, performance additives have become indispensable tools in the quest for superior product performance and efficiency.

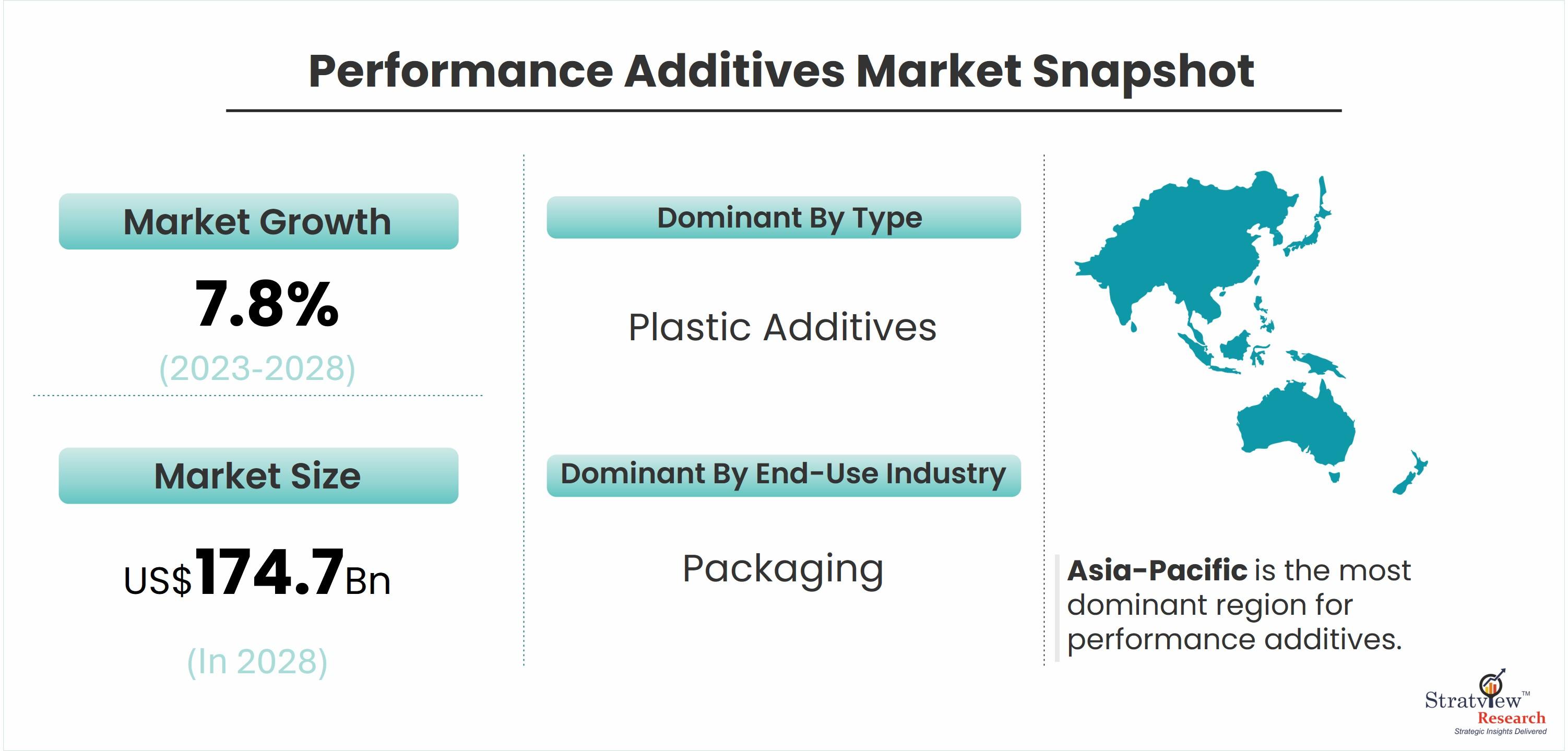

According to Stratview Research, the performance additives market was estimated at USD 111.32 billion in 2022 and is likely to grow at a CAGR of 7.8% during 2023-2028 to reach USD 174.70 billion in 2028.

1. Enhancing Product Performance

Performance additives play a crucial role in improving the performance characteristics of materials and products. In the automotive industry, for instance, additives are used to enhance fuel efficiency, reduce emissions, and improve the durability of engine components. These additives help manufacturers produce vehicles that are more efficient, reliable, and environmentally friendly. Similarly, in the construction sector, performance additives enhance the properties of concrete and asphalt, making them more resistant to wear and weather conditions.

2. Boosting Durability and Longevity

One of the significant benefits of performance additives is their ability to boost the durability and longevity of products. Additives can enhance resistance to corrosion, UV radiation, and thermal degradation, extending the lifespan of materials and reducing the need for frequent replacements. For example, additives used in coatings and plastics improve resistance to environmental factors, ensuring that products maintain their appearance and functionality over time. This increased durability translates to cost savings for manufacturers and consumers alike.

3. Driving Innovation in Materials

Performance additives are driving innovation in material science by enabling the development of new and advanced materials. Nanotechnology, for example, has led to the creation of nanocomposites that offer superior strength, flexibility, and lightweight properties. These advanced materials are used in various applications, including aerospace, electronics, and medical devices. By pushing the boundaries of material performance, additives are facilitating the creation of cutting-edge products with enhanced capabilities.

4. Supporting Sustainability Initiatives

Sustainability is a growing concern in modern manufacturing, and performance additives are contributing to greener practices. Additives that improve the efficiency of production processes, reduce waste, and enhance the recyclability of materials align with the industry's shift towards sustainable practices. Biodegradable additives and those derived from renewable resources are gaining popularity as manufacturers seek to reduce their environmental footprint and meet regulatory requirements.

5. Customizing Solutions for Specific Needs

Customization is a key trend in the performance additives market. Manufacturers are increasingly seeking tailored solutions that address specific performance challenges and application requirements. Additives can be customized to achieve desired properties, such as improved thermal stability, enhanced strength, or better flowability. This level of customization enables manufacturers to optimize product performance and meet the unique demands of different industries.

Conclusion

Performance additives are shaping modern manufacturing by enhancing product performance, boosting durability, driving innovation, supporting sustainability, and enabling customization. As industries continue to evolve and face new challenges, the role of performance additives will become increasingly vital in achieving superior product quality and operational efficiency. By leveraging the benefits of these additives, manufacturers can stay competitive and meet the ever-growing demands of the market.

- Questions and Answers

- Opinion

- Story/Motivational/Inspiring

- Technology

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News

- Culture

- War machines and policy