The Versatility and Benefits of PP Sheets: An Essential Material for Modern Applications

Polypropylene (PP) sheets are gaining popularity across various industries due to their exceptional properties and versatile applications. Known for their durability, chemical resistance, and ease of fabrication, P p sheet Price in India are used in everything from packaging to automotive parts. This blog will explore what PP sheets are, their key characteristics, and the wide range of applications that make them an essential material in modern manufacturing.

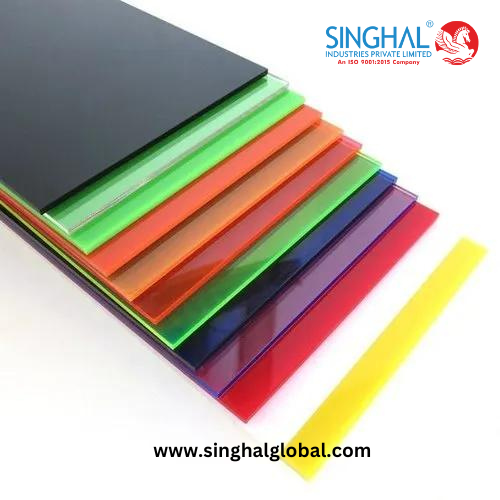

What Are PP Sheets?

PP sheets are made from polypropylene, a thermoplastic polymer that is known for its strength and flexibility. These sheets are produced through a process called extrusion, where melted polypropylene is shaped into Pp sheet price in kolkata, flat sheets. The resulting product is lightweight, yet incredibly durable, and can be easily cut, shaped, and welded to meet specific requirements.

Key Characteristics of PP Sheets

1. Durability and Strength

One of the primary reasons for the widespread use of PP sheets is their durability and strength. They can withstand significant impact and stress without cracking or breaking. This makes them ideal for applications that require a tough and long-lasting material.

2. Chemical and Moisture Resistance

PP sheets are highly resistant to a wide range of chemicals, including acids, alkalis, and solvents. This chemical resistance makes them suitable for use in environments where exposure to corrosive substances is common. Additionally, PP sheets are impervious to moisture, which prevents them from warping or degrading when exposed to water.

3. Lightweight

Despite their strength, PP sheets are remarkably lightweight. This characteristic makes them easy to handle and transport, reducing costs and improving efficiency in various applications.

4. Versatility

PP sheets can be easily cut, shaped, and welded, allowing for customization to meet specific needs. They can also be treated with various additives to enhance their properties, such as UV stabilizers for outdoor use or flame retardants for improved safety.

5. Eco-Friendly

PP sheets are environmentally friendly as they are recyclable. The recycling process for polypropylene is straightforward and cost-effective, making it a sustainable choice for many industries. Additionally, the production of PP sheets generates minimal waste compared to other materials.

Applications of PP Sheets

1. Packaging

One of the most common uses of PP sheets is in the packaging industry. Their durability and moisture resistance make them ideal for creating sturdy, reliable packaging solutions. PP sheets are used to make boxes, containers, and trays that protect products during transportation and storage. They are also used for food packaging due to their non-toxic nature and resistance to moisture and contaminants.

2. Automotive

In the automotive industry, PP sheets are used to manufacture various components, including dashboards, door panels, and interior trim. The lightweight nature of PP sheets helps reduce the overall weight of vehicles, improving fuel efficiency and performance. Additionally, their resistance to chemicals and moisture ensures longevity and durability in harsh automotive environments.

3. Construction

PP sheets are increasingly used in the construction industry for applications such as wall cladding, roofing, and flooring. Their strength and durability make them ideal for structural applications, while their resistance to moisture and chemicals ensures longevity in various environmental conditions. PP sheets are also used for insulation and as vapor barriers to improve energy efficiency in buildings.

4. Advertising and Signage

The advertising and signage industry utilizes PP sheets for creating durable and lightweight signs, displays, and billboards. The ease of printing on PP sheets, combined with their resistance to weather and UV radiation, makes them an excellent choice for outdoor advertising. Additionally, their lightweight nature allows for easy installation and transportation.

5. Medical and Healthcare

PP sheets are used in the medical and healthcare sector to manufacture items such as sterilization trays, medical device components, and laboratory equipment. Their chemical resistance and ability to withstand high temperatures make them suitable for use in sterile environments. Additionally, PP sheets are non-toxic and biocompatible, ensuring safety for medical applications.

6. Industrial Applications

In industrial settings, PP sheets are used to create a variety of components and equipment. Their resistance to chemicals and moisture makes them suitable for use in chemical processing plants, water treatment facilities, and other harsh environments. PP sheets are also used to make tanks, piping, and ductwork, where their durability and strength are essential.

Benefits of Using PP Sheets

1. Cost-Effective

PP sheets are relatively inexpensive compared to other materials with similar properties. Their durability and long lifespan mean that products made from PP sheets do not need to be replaced as often, reducing overall costs. Additionally, the lightweight nature of PP sheets reduces transportation and handling costs.

2. Easy to Fabricate

PP sheets are easy to work with, making them a popular choice for manufacturers. They can be cut, shaped, and welded using standard equipment, allowing for quick and efficient production. This ease of fabrication also allows for customization to meet specific needs and requirements.

3. Sustainable

As mentioned earlier, PP sheets are recyclable, making them an environmentally friendly choice. The recycling process for polypropylene is efficient, and the material can be reused in various applications without losing its properties. This sustainability makes PP sheets an attractive option for businesses looking to reduce their environmental footprint.

4. Versatile

The versatility of PP sheets means they can be used in a wide range of applications. Whether it's for packaging, automotive components, construction materials, or medical devices, PP sheets offer the properties needed for reliable and efficient performance. Their ability to be customized with various additives further enhances their versatility.

5. Safe and Non-Toxic

PP sheets are non-toxic and safe for use in applications that require direct contact with food, medical devices, and other sensitive products. Their resistance to chemicals and ability to withstand high temperatures ensure they do not release harmful substances, making them a safe choice for various industries.

Conclusion

PP sheets are a versatile and essential material in modern manufacturing, offering a range of benefits that make them suitable for numerous applications. Their durability, chemical resistance, lightweight nature, and ease of fabrication make them a cost-effective and sustainable choice for industries such as packaging, automotive, construction, advertising, medical, and industrial applications. As businesses continue to seek reliable and eco-friendly materials, Pp sheets manufacturer in india are set to play an increasingly important role in meeting these demands. Embrace the versatility and benefits of PP sheets and discover how they can enhance your products and processes.

Frequently Asked Questions (FAQs):

Q1: What are the main applications of PP sheets produced by Singhal Industries?

PP sheets produced by Singhal Industries are used across various industries due to their exceptional properties. In the packaging industry, they are utilized to create sturdy and moisture-resistant packaging solutions such as boxes, containers, and trays. The automotive industry benefits from their lightweight nature, using them for dashboards, door panels, and interior trim, which help improve fuel efficiency. In construction, PP sheets are ideal for wall cladding, roofing, and flooring due to their strength and durability. Additionally, they are widely used in advertising for signs and displays, in the medical sector for sterilization trays and device components, and in industrial settings for chemical-resistant tanks and piping.

Q2: Why are PP sheets from Singhal Industries considered a cost-effective and sustainable choice?

PP sheets from Singhal Industries are cost-effective due to their relatively low production costs and long lifespan, which reduce the need for frequent replacements. Their lightweight nature also lowers transportation and handling costs. Sustainability is another significant advantage, as these sheets are recyclable and the recycling process is efficient, allowing the material to be reused without losing its properties. The production process generates minimal waste, making PP sheets an environmentally friendly option for businesses aiming to reduce their environmental footprint.

Q3: What makes PP sheets from Singhal Industries safe and easy to fabricate?

Singhal Industries' PP sheets are safe and non-toxic, making them suitable for applications involving direct contact with food and medical devices. Their chemical resistance and ability to withstand high temperatures ensure that they do not release harmful substances, ensuring safety in various uses. Additionally, these sheets are easy to work with and can be cut, shaped, and welded using standard equipment. This ease of fabrication allows for quick and efficient production, as well as customization to meet specific needs and requirements, enhancing their appeal in diverse applications.

- Questions and Answers

- Opinion

- Story/Motivational/Inspiring

- Technology

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News

- Culture

- War machines and policy